Collaborative Factory Layout

Enabling Worldwide Manufacturing Teams to Collaborate in XR

What's Today's Challenge?

Rarely are products completely developed in a single location, neither are they built in a single location. Moreover, a lot of the equipment used to build the product is outsourced to a wide group of suppliers. Bringing all of that data together so all parties can collaborate on the factory or work cell layout offers enormous benefits and cost savings.

Factory Layout provides a full scale and in context environment for defining, reviewing, editing and validating shop floor layouts. This can be done collaboratively with colleagues in different offices or countries, and even suppliers can be involved. Libraries of existing plant, tools and equipment can be automatically uploaded and used in a collaborative team review session, no knowledge of CAD is needed.

It enables companies to avoid costly layout redesign, by enabling all parties involved to review the layout collaboratively, make or recommend changes, and capture those decisions for later review by staff who could not attend the session.

Benefits and Cost Savings

Reduce Costs

Products can be tested for the first time when they are available as digital prototypes, before any physical equipment is built or delivered. Buildings, plant, work cells, lines and the complete factory can be checked in detail by layout engineers, installation or service personnel. Any issues can be recorded and sent back to CAD engineers to make modifications. This saves expensive on-site modifications.

Collaborative Team Work

By being able to collaborate, team work is highly enhanced by gathering people around a full digital (virtual) model of the factory and immersing them in it. At full scale it is possible to better understand the technical challenges, quickly approve design amendments, iterate and make decisions. It saves money on travel and reduces time to production.

Scale and Context

Factories by their very nature are large scale structures. Seeing your factory in extended reality lets you escape the cramped confines of your computer monitor, and harness your whole brain. Experience your 3D design, rather than viewing it on a flat 2D computer screen. Collaborate in real-time, securely and remotely using intuitive XR tools for more effective decision making.

See the Full Picture

Factory Layout enables you to review a full digital representation of your facilities and equipment. It brings together your building data, whether in CAD or scanned form, machinery and equipment data designed in specialist systems such as Technomatix or Delmia, and product data designed in mechanical CAD, including CAD data from your tooling and equipment suppliers. All seen at full scale and in the context of each other. Eliminate ambiguity and reduce the time for decision making.

Connect and Collaborate

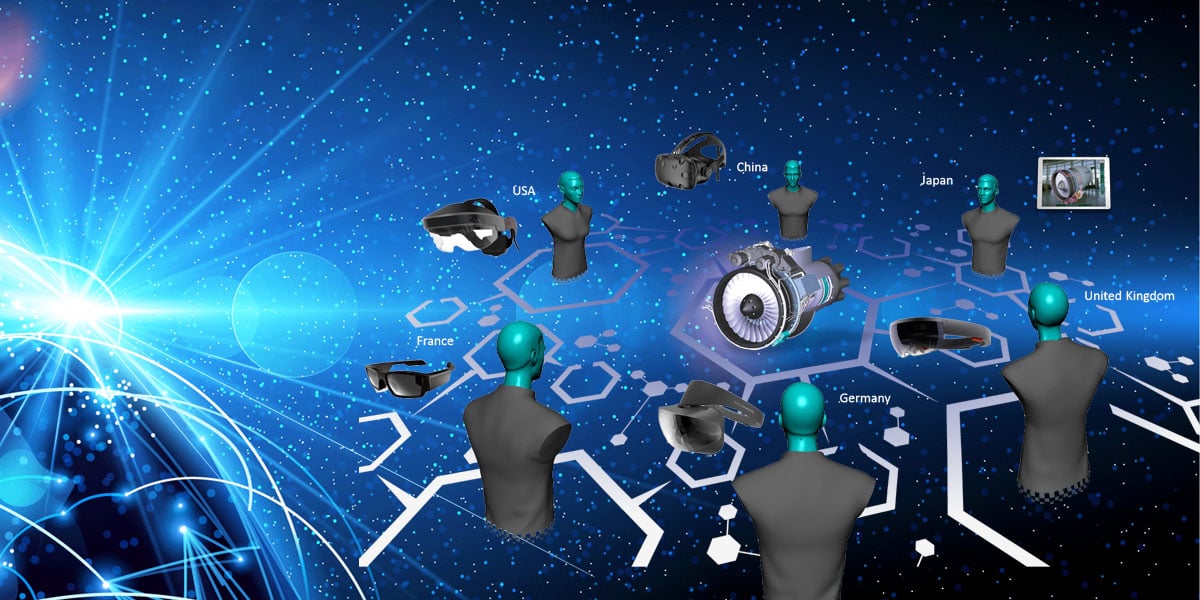

By enabling your teams to connect and collaborate ensures faster product development when collaboration isn’t confined to the walls of an organization. Let your team work on the same layout model from remote locations using multiple XR technologies for shorter time-to-market and increased efficiency.

Improve Decision Making

Using extended reality, you can make better decisions, save time and identify design challenges together with your colleagues, suppliers or customers. Increase common understanding, facilitate more creative discussions and solve real world problems quickly.

Collaboration Solutions

Collaborative Design Reviews

Rarely are products completely developed in a single location with the luxury of co-located development teams. Undertaking Design Reviews in XR collaboratively eliminates that problem.

Collaborative Factory Layout

Factory Layout provides a full scale and in context environment for defining, reviewing, editing and validating shop floor layouts collaboratively with colleagues in different offices or countries.

Data and Technology Agnostic

TheoremXR supports all XR technologies: Augmented, Mixed and Virtual. You can start with whatever technology is best for you and transition or change at no cost as your data is usable in all.

Catchup on the Latest TheoremXR News

Demonstration Request

Register now to request your free demonstration of the TheoremXR product suite.

In just a few simple steps, we will be able to validate your request based upon the details you provide.

Note: Please use your company email address for validation purposes as we will not respond to personal email accounts.

-

Complete all of your required details.

-

Let us know which TheoremXR product you are looking to learn more about.

-

If you have a specific use case that you would like to discuss then please let us know.

-

We will contact you to discuss suitable days and times and get everything setup.

-

Please only use your company email address for validation purposes as we will not respond to personal email accounts