How to Get CAD Into XR

Understand the differences

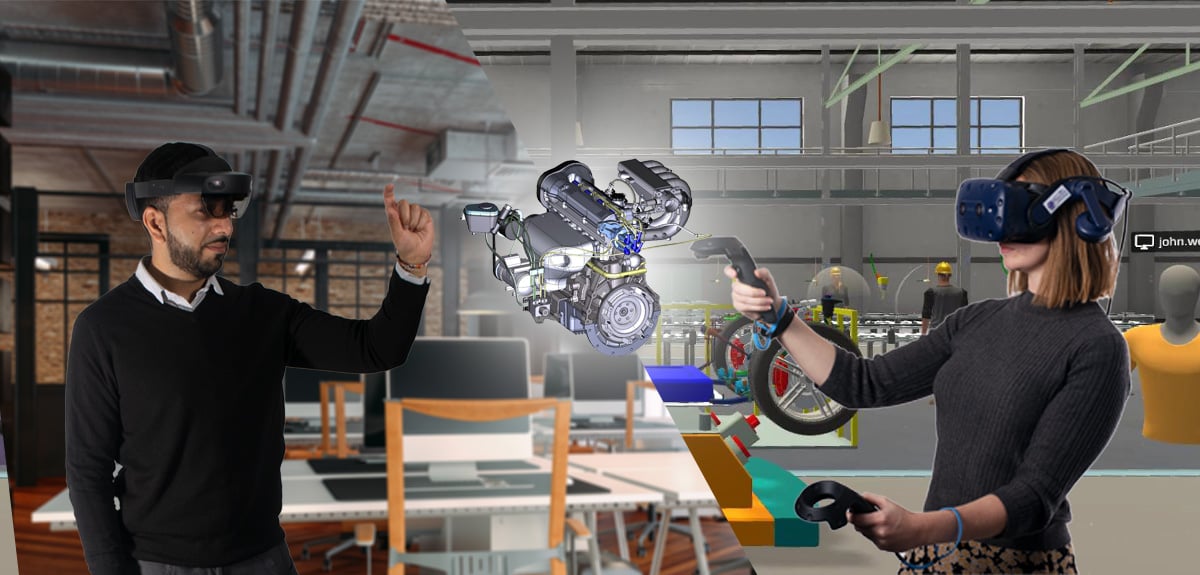

Work collaboratively at scale and in context with your 3D CAD assets

Visualize and share your 3D CAD and PLM assets quickly and easily in an Augmented, Mixed or Virtual Reality environment, spatially, at full scale and in context.

Work collaboratively to undertake everyday engineering tasks (design reviews, factory layout or visual digital twin), and help to reduce costs, improve product quality and support the faster development of products and manufacturing processes across the enterprise.

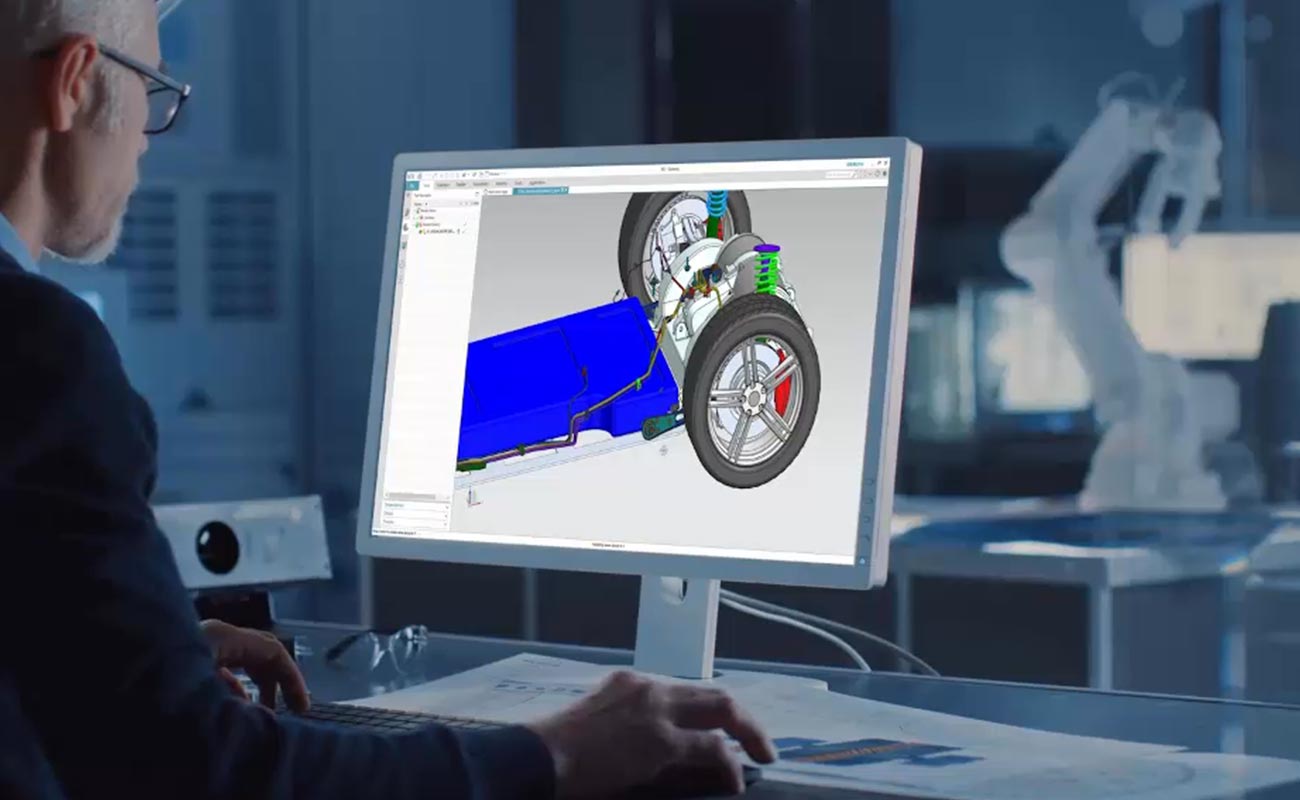

The video below will help you to see the difference between 3D data in CAD vs the same 3D CAD Data in XR

3D data in CAD vs the same 3D CAD Data in XR

Which technology is right for your use case?

Augmented Reality (AR), Mixed Reality (MR), Virtual Reality (VR)... or all three?

PODCAST: Getting Started in XR

Listen to our recent podcast between Mark Sage of the AREA and Stuart Thurlby CEO of Theorem Solutions discussing what you need to think about in order to start your journey into XR.

Everyday Use Cases to Think About

.jpg?width=1920&height=1080&name=Theorem-XR-Suite%20(Time%200_00_50%3B26).jpg)

Visualization

Visualize 3D CAD data at full scale and in context and interrogate the data in Augmented, Mixed and Virtual Reality devices.

Design Review

Collaboratively review design milestones, at scale and in context. Make comments and annotate the design for later review.

Factory Layout

Individuals or groups of engineers can layout work cells, production lines or full factories using Mixed and/or Virtual Reality.

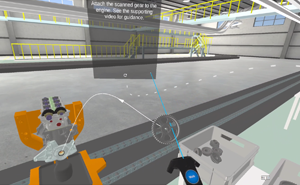

Training Guides

Create Training or Work instructions to teach front line workers build processes, or guide experienced workers during complex tasks using Mixed or Virtual Reality headsets and Desktop devices.

Visual Digital Twin

The Visual Digital Twin delivers a rich 3D digital model allowing it to be overlaid on top of a physical object and tracked. For use in inspection, training, packaging and in support of a full Digital twin.

CAD Data Preparation

The Visualization Pipeline is a fully automated solution that prepares your CAD data for use in XR. It can be run in batch mode, processing data triggered by PLM processes, or for a CAD user it's as simple as "save as". Or for the non-CAD user drag and drop from the file system.

We're here to help

Talk to our XR team today. If you aren't sure where to start or which device would most suit your use case; perhaps you don't have a specific use case defined yet? We can help you to make sense of the market and what is available today with an unbiased and neutral opinion.

If you are at the next stage of your XR journey and have already chosen your use case and device, but are struggling to get existing data on to your HMD, we can demonstrate how a simple drag and drop solution can be implemented.

At whichever stage you are at in your XR journey, we are here to help.

The Cognitive Gap: Understand the science behind working at full scale and in context

Recent Success Stories

Learn how Valiant TMS adopt TheoremXR for their Merged Reality Concept

Theorem’s Visualization Experience software has provided Valiant TMS with a unique opportunity to visualize 3D CAD models placed directly over real world equipment, tooling and components.

Valiant TMS’ use of the software has improved their ability to quickly

inspect tooling and components prior to acceptance from their vendors, ensuring that as-built components match as-designed plans, saving time and money at the assembly site.

Learn how NCR digitally transform their design reviews with TheoremXR

ATM manufacturer NCR (National Cash Registers) have revolutionised their design review and prototyping processes with the help of TheoremXR, saving an estimated £390,000 in their first year with a ROI in under two months!

Their process prior to using Theorem XR was to physically manufacture multiple versions of the product to conduct their design review, before sending the final design to production.

Talk to us today!

Catchup on the latest TheoremXR news

Demonstration Request

Register now to request your free demonstration of the TheoremXR product suite.

In just a few simple steps, we will be able to validate your request based upon the details you provide.

Note: Please use your company email address for validation purposes as we will not respond to personal email accounts.

-

Complete all of your required details.

-

Let us know which TheoremXR product you are looking to learn more about.

-

If you have a specific use case that you would like to discuss then please let us know.

-

We will contact you to discuss suitable days and times and get everything setup.

-

Please only use your company email address for validation purposes as we will not respond to personal email accounts