Extended Reality - XR

Augmented, Mixed and Virtual Reality for the Engineering Metaverse.

Revolutionize Your Design and Manufacturing Processes with Extended Reality (XR)

Are you seeking innovative solutions to streamline your design and manufacturing processes in the latest technologies? Look no further than TheoremXR. Our cutting-edge technology harnesses the power of Extended Reality - XR (Augmented, Mixed and Virtual Reality) to empower companies to extend the value of their rich 3D CAD data.

Through fully automated CAD data preparation, we offer a suite of out-of-the-box XR Experiences that can be tailored to address a number of engineering and manufacturing challenges.

TheoremXR has been developed to maximize the value of your engineering design data, streamline processes, and save valuable time and resource

Automated Data Preparation and Optimisation

Remove the time, costs and resource required to manually prepare and optimise your 3D CAD data and design assets into formats suitable for XR experiences.

Early Issue Detection and Resolution

Identify and address design issues early in the process, minimizing delays and reducing rework.

Enhanced Collaboration and Data Interaction

Enable seamless collaboration among distributed teams, facilitating faster decision-making and reducing travel costs.

Full-scale and In-context Visualization

Visualize your designs at full scale and in their intended context, enabling better decision-making and reducing costly errors.

Improved Customer Feedback and Communication

Enhance communication with customers by providing immersive experiences that enable them to better understand and provide feedback on designs.

Real-Time Decision Making

Make informed decisions in real-time, leading to increased efficiency and agility in your workflows.

Time and Cost Savings

Streamline your design and manufacturing processes, saving both time and money. Identify and address design issues early in the process, minimizing costly rework and delays.

How can TheoremXR work for you?

TheoremXR enables companies to seamlessly extend the value of their rich CAD data into Extended Reality (XR), revolutionizing engineering and manufacturing workflows.

Our XR Experiences offer comprehensive solutions for full-scale and context-driven Design Review, Factory Layout and Planning, Visualization, and the Visual Digital Twin.

Supporting Augmented, Mixed and Virtual Reality devices, our solutions enable collaborative work across remote teams and home-based staff, delivering immersive experiences accessible from any device —including desktops.

TheoremXR enables you to make the right choices

If you aren't sure where to start or which device would most suit your use case; perhaps you don't have a specific use case defined yet? We can help you to make sense of the market and what is available today with an unbiased and neutral opinion.

If you are at the next stage of your XR journey and have already chosen your use case and device, but are struggling to get existing data on to your device, we can demonstrate how a simple drag and drop solution can be implemented.

At whichever stage you are at in your XR journey, we are here to help. Talk to our XR team today.

Helping to Maximise Your XR Strategy

We offer a data and device neutral approach to extended reality.

Fast, efficient automated CAD Data Preparation and optimization.

For use in our XR applications, or your own tailored XR experiences.

We support a large variety of CAD and visualization input formats that can be optimized for use in XR.

Full scale in context visualization to meet your engineering focused use case.

We support the latest Augmented, Mixed and Virtual Reality devices.

Remote Collaboration supported throughout our XR product suite.

Large scale high quality rendering for Microsoft HoloLens 2 using Azure Remote Render ARR.

Enable you to move away from in-house development to COTS maintained and documented XR products.

Remove the Time and Costs Associated with Data Preparation & Optimization for XR

Leveraging the Theorem Visualization Pipeline, engineering companies can effortlessly transform their 3D CAD data and design assets into immersive XR experiences. Our fully automated process streamlines the preparation of CAD data directly into TheoremXR, or facilitates the creation of Unity or Unreal assets for custom XR solutions.

Seamlessly integrate the Visualization Pipeline into your PLM workflow, or empower CAD users to save files directly into XR. Even non-CAD users can effortlessly contribute by simply dragging and dropping files onto the pipeline, which automatically generates XR assets. Revolutionize your data preparation process with TheoremXR.

Supporting a Range of Engineering and Manufacturing Use Cases

TheoremXR optimises multiple design formats via a fully automated workflow, requiring no manual intervention. Our solutions enable you to achieve high-quality 3D content for use in our engineering-focused experiences, or for your own tailored XR applications.

Visualization

Visualize 3D CAD data at full scale and in context and interrogate the data in Augmented, Mixed and Virtual Reality devices.

Collaboration

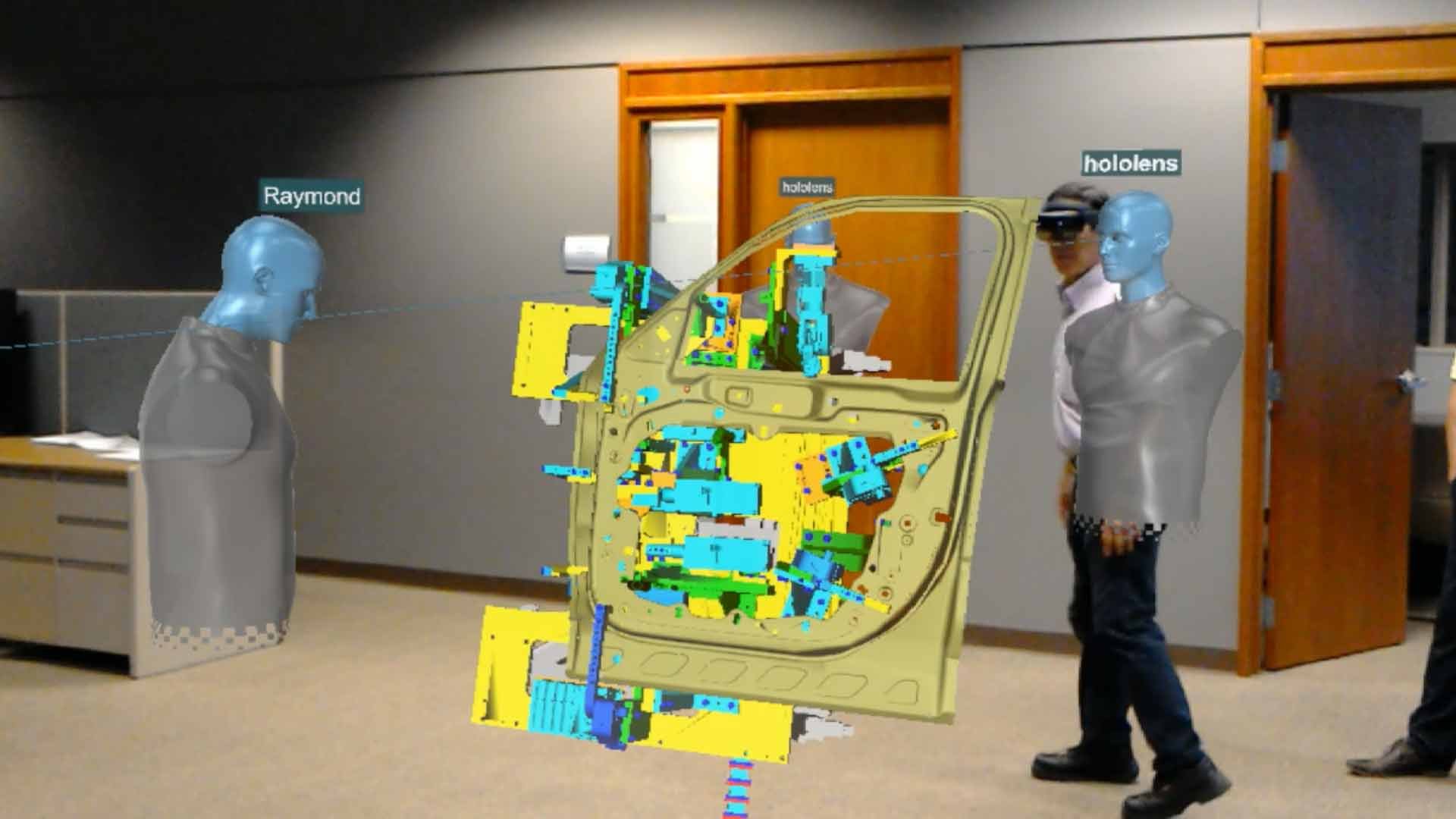

Collaborate in real time from anywhere. Bring teams together to review, train, and validate 3D designs at full scale.

Design Review

Collaboratively review design milestones, at scale and in context. Make comments and annotate the design for later review.

Factory Layout

Individuals or groups of engineers can layout work cells, production lines or full factories using Mixed and/or Virtual Reality.

Visual Digital Twin

The Visual Digital Twin delivers a rich 3D digital model allowing it to be overlaid on top of a physical object and tracked. For use in inspection, training, packaging and in support of a full Digital twin.

USER STORY

Valiant TMS - Merged Reality Concept

"We have several cases where traditionally it may have taken days to carry out a task, required travel time and related expenses and may have delayed our project timing.

We’ve been able to do many of these tasks in a matter of hours, without having to travel. It’s much more efficient." - Valiant TMS

Learn how Valiant TMS leveraged TheoremXR for their Merged Reality Concept using Augmented and Mixed Reality technology.

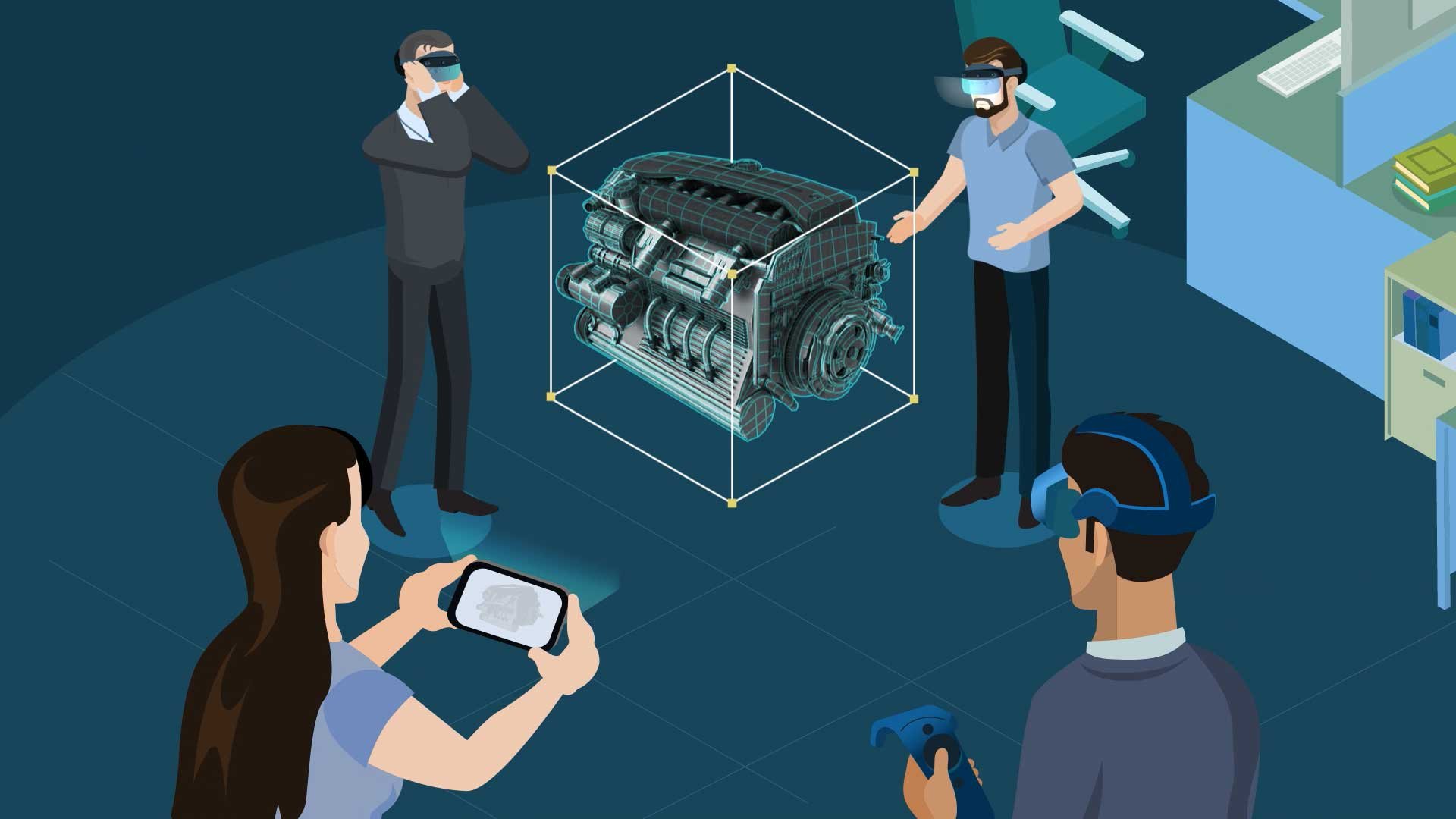

Enabling Multi-User XR Collaboration

Multi-User XR Collaboration offers an innovative solution for teams to work together seamlessly, transcending geographical barriers and enhancing productivity. In today's interconnected world, where remote work and dispersed teams are increasingly common, TheoremXR provides a dynamic environment for real-time collaboration.

- Immersive design reviews: Evaluate milestones and designs in shared virtual spaces.

- Optimized layouts: Collaboratively review and optimize factory or workstation layouts.

- Remote training: Engage remote staff with immersive simulations for hands-on learning.

- Data security: Ensure confidentiality with robust encryption and access controls.

- Enhanced productivity: Accelerate decision-making and foster creativity in a connected environment.

Supporting Augmented, Mixed and Virtual Reality technologies and devices

The term Extended Reality (XR) encompasses Augmented, Mixed and Virtual Reality, and each different technology comes with it’s own set of features, benefits and associated device types. But which one is right for you and your use case?

Which Phase of XR Adoption are you?

Research and Development

You're not really sure what you can use XR for and don't know which device is best for you, but would like to understand what your options are.

Proof of Concept

You've started your XR journey and have made an initial investment but need help to understand how to build a concrete business case that will get buy in from senior management.

Adopter

You've implemented your XR strategy; purchased devices and have real world use cases, but would like help to streamline and enhance processes, data optimization, take the next step on from an out of the box solution or are struggling to work with large scale data sets.

What is the Metaverse and How Will it Change Engineering?

The metaverse could change everything from entertainment, shopping, education, and the workplace. In the future, many aspects of our lives may take place within the metaverse — in an immersive, fully digital world accessed using headsets.

Catchup on the latest TheoremXR news

XR is at the forefront of CAD data Visualization

TheoremXR exists to solve the problem of the cognitive gap. The cognitive gap is the relationship between the form in which information is presented, and the context in which it is applied. Advanced visualization, which places information in context with the environment to which it refers, is the solution.

Why TheoremXR?

TheoremXR is a complementary technology that works for the individual, the enterprise, at all levels and at all stages of the Extended Reality journey, enabling the user to optimize, visualize and collaborate around their design data. Backed by 30+ years of CAD data optimization and preparation experience, as a member of the Microsoft Mixed Reality Partner Program (MRPP), and partner to all major CAD vendors, TheoremXR provides a robust and agile solution for now and the future.

Demonstration Request

Register now to request your free demonstration of the TheoremXR product suite.

In just a few simple steps, we will be able to validate your request based upon the details you provide.

Note: Please use your company email address for validation purposes as we will not respond to personal email accounts.

-

Complete all of your required details.

-

Let us know which TheoremXR product you are looking to learn more about.

-

If you have a specific use case that you would like to discuss then please let us know.

-

We will contact you to discuss suitable days and times and get everything setup.

-

Please only use your company email address for validation purposes as we will not respond to personal email accounts