Many companies are exploring and investing in Extended Reality (XR) technologies as a way of enhancing their engineering and manufacturing processes, and extending the use of their 3D design data for downstream purposes. XR has many uses, from design reviews to factory layout planning. By allowing users to visualize their CAD data in an intuitive and understandable way, XR opens up new possibilities of interacting with, and collaborating around your design data.

However, despite the many benefits of XR, we often hear the same concerns and issues regarding data performance and how to properly prepare it for use within a particular device type. Augmented, Mixed, and Virtual Reality devices have their own limitations, which need to be addressed when preparing data for visualization. Companies are having difficulty implementing their XR strategy because of complications arising as a direct result of non-optimized data.

There are many different options for optimizing your data, and the best option or combination will depend upon your use case. Shrink Wrapping, Part Culling, Model Decimation / Tessellation, and Altering Assembly Structure are all potential options to help improve the performance of your data and also the end-user experience. Not only does your data need to be in the correct format, but also useable.

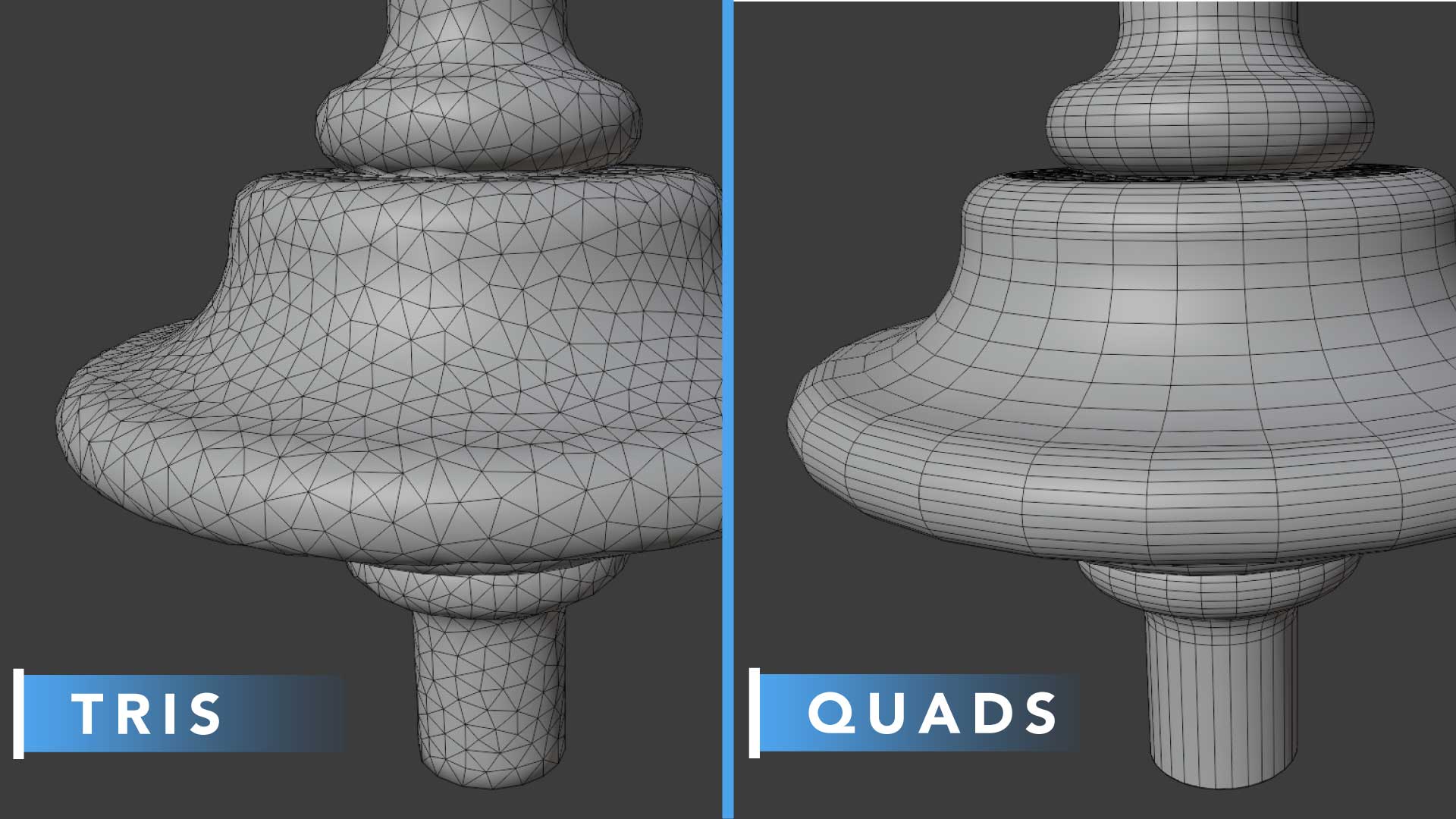

3D models can be made up of millions of polygons, most commonly triangles, dependent upon their complexity. The greater the number of polygons, the higher the quality of the model, resulting in a more intensive load to the renderer, which in turn can reduce performance. As a result, optimizing data for use in an XR device often requires sacrificing the quality of the model; however, there are ways to optimize your data while minimizing this loss of quality – it all depends on the use case.

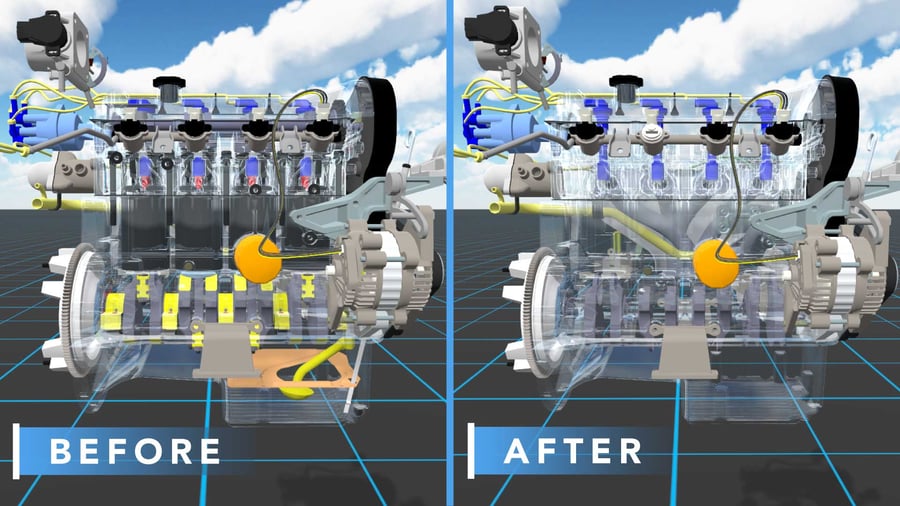

Shrink Wrapping

With shrink wrapping, data is optimized by removing the internal components of a model, reducing the polygon count and making the model quicker to render in XR. Since this method removes the internal parts of the model, this method is most useful when you only need to see the exterior of a model, which can still be very high quality.

Part Culling

Similarly to shrink wrapping, part culling reduces the overall poly count by removing whole parts of a model, in this case, unnecessary and smaller parts rather than internal components. This includes things like screws or caps that may be important to the model but do not need to be reviewed in an XR session.

Using this method, users are still able to review both external and internal components in detail, which is particularly useful as part of a design review for example, where users are reviewing multiple parts of a model and need to view them in high-quality in order to spot errors and make adjustments.

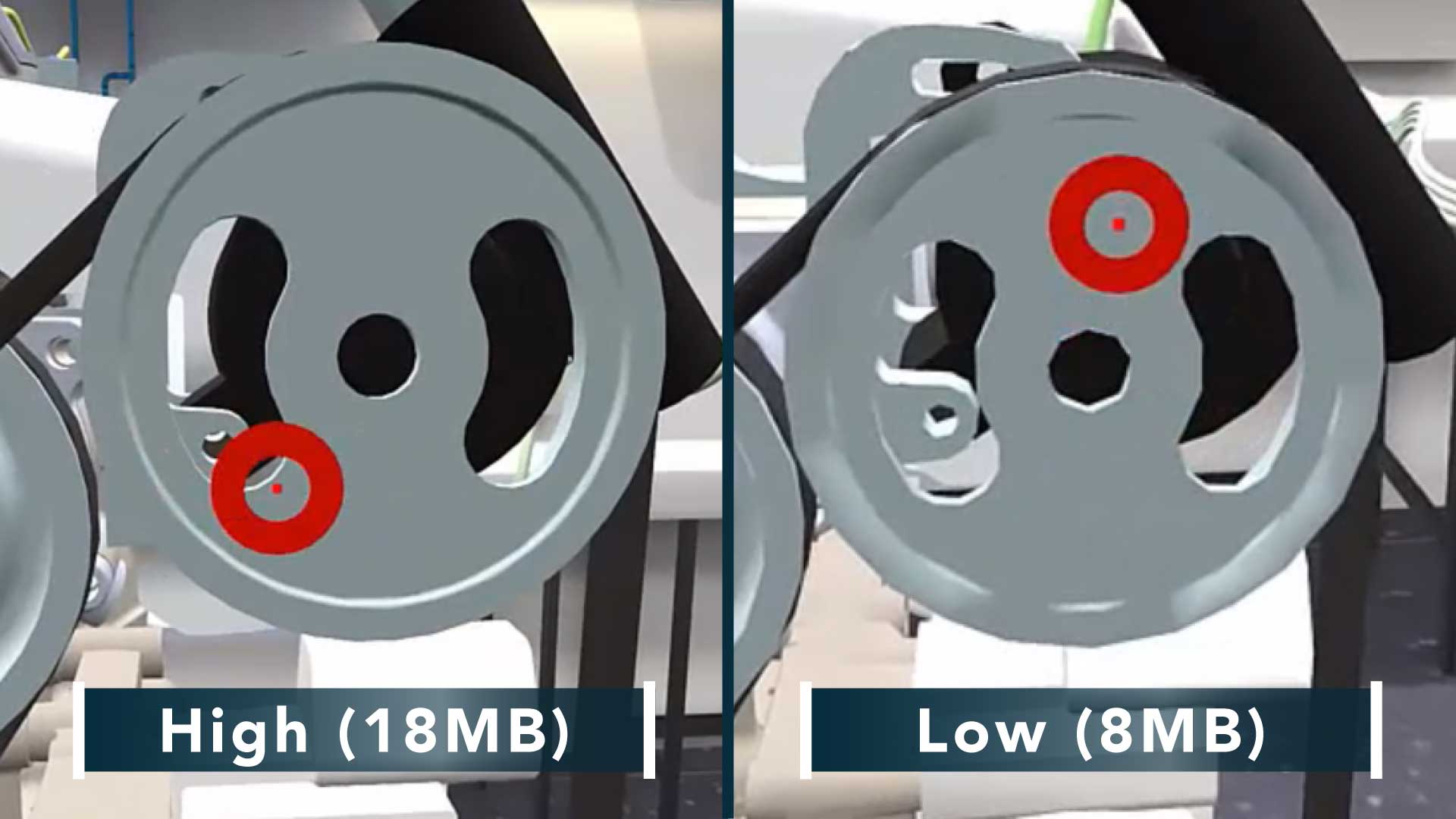

Model Decimation / Tessellation

Model Decimation / Tessellation is a process that reduces the polygon count for the whole model by converting collections of many smaller polygons into a larger shape which reduces the level of detail. With this method, larger tolerances will result in a lower-quality model, which may be acceptable in some situations. For example, when planning a factory layout, you may be rendering many models, but they do not need to be detailed if you only need to check if a part fits in a space.

However, Model Decimation / Tessellation can still be used when high-quality models are required. More conservative settings will result in a model where the reduction in quality is so minor that it isn’t noticeable. Although in this case the polygon count isn’t reduced as much, this method can be particularly effective when paired with other optimization methods, to further improve performance in XR.

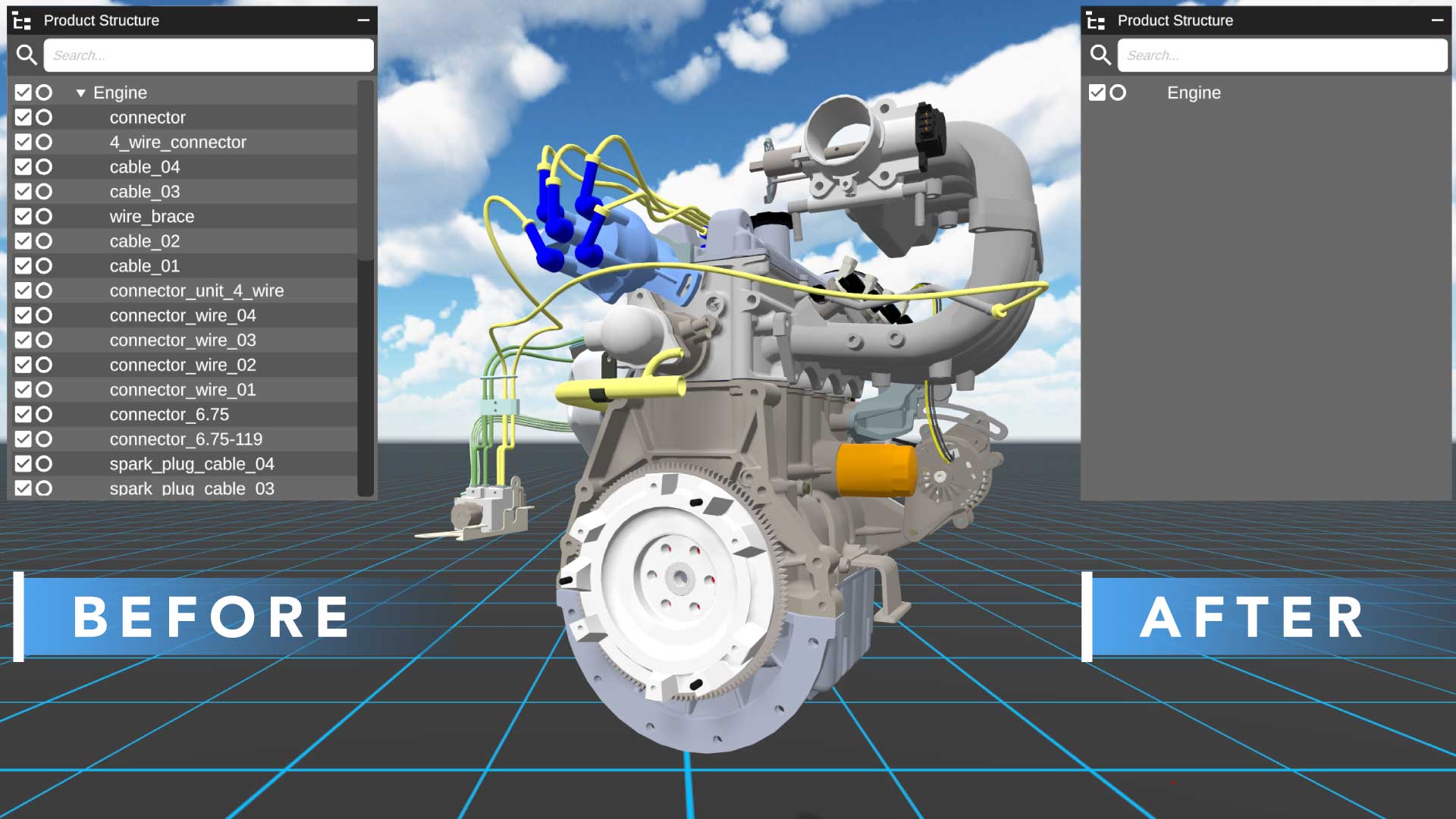

Assembly Structure

When bringing CAD data into XR, users are also able to bring through features like the assembly structure that they are familiar with from their CAD system. This assembly structure can be very useful when navigating a model, by allowing you to select or hide specific parts. However, if you don’t need to examine a model in detail then you can improve performance in XR by removing the assembly structure.

The Visualization Pipeline

The optimization methods we’ve discussed can make your plans for XR much more viable; however, you will still need a solution in order to implement them. Sometimes data preparation and optimization can be a frustrating and time-consuming process particularly if you are uploading multiple models or using multiple types of data.

Theorem’s Visualization Pipeline is a server-based solution designed to automate the preparation of your design data for a quick and easy process that saves time and money by reducing the need for manual activity. Users are able to upload their CAD data to the Visualization Pipeline directly from within their CAD system using save as, or alternatively users can drag and drop files using Theorem’s UI. The Visualization Pipeline can also be connected to your PLM system for an integrated and simple process.

The Visualization Pipeline gives users control over how their data is optimized. When preparing data for XR there is no one-size-fits-all all approach and every use case will have different requirements, which is why it is important to understand the options available. Along with this, the Visualization Pipeline offers multiple import options. These include material mapping, which can ensure a consistent colour pallet or allow users to utilize application-specific materials; quadding, which can make material mapping easier for models in an FBX format; defeaturing, which allows users to reduce the amount of information, resulting in smaller file sizes; and extract metadata, which allows extracted metadata to be available in XR experiences.

To Sum Up

Extended reality can help users to better understand and contextualize CAD data, however without preparing and optimizing your data, you could have poor performance in XR. The best optimization methods will vary from use case to use case, but a solution like Theorem’s Visualization Pipeline can give you all the tools required to utilize multiple optimization methods in a way that is simple and efficient.

To learn more, visit the TheoremXR page or get in touch with our team of specialists today. We’re here at every step of your XR journey. You can also follow us on LinkedIn and Twitter for the latest XR news and updates.