In engineering and manufacturing, digital collaboration is an essential part of the design process. The importance of collaborative working through digital channels was highlighted during the COVID-19 pandemic and many people have continued to opt for remote working. But even before lockdowns gave rise to working from home, collaboration between globally distributed teams would require remote communication. However, this does not remove the need for physical interaction.

Reduce the Need for In-Person Meetings

Despite increasing remote working, there are still many benefits to office work. In the “Working from Home Around the Globe: 2023 Report” conducted by EconPol that surveyed employees on their opinions about working from home, the main benefits of working on the businesses’ premises are socializing with co-workers (said by 62% of participants) and face-to-face collaboration (said by 54.4% of participants). Talking with co-workers and collaborating in person can make it easier to generate ideas, uncover issues, and brainstorm solutions.

However, with the popularity of remote work increasing, how can businesses combine the benefits of office working and working from home? Technology. Extended Reality, Spatial Computing the Metaverse. For the purpose of this post we are going to focus upon Extended Reality.

Extended Reality (XR) allows for more effective collaboration and is more interactive than typical video calling with applications like Microsoft Teams and Zoom that have become the norm. Although XR may seem like a niche market, its popularity continues to grow. In fact, IMARC reports that the XR global market size reached US$ 92.5 Billion in 2023 and is expected to grow 39.2% throughout 2024.

When reviewing 3D data using an XR device, users can visualize, engage, and interact with their design data at scale and in context, which is more intuitive than having to interpret 3D data viewed on a screen. This disconnect between viewing 3D models on a 2D screen is known as the “cognitive gap”. XR is a great way to close this gap, allowing users to fully understand their 3D design data.

Because of this, XR can significantly reduce the need for in-person meetings. It allows fully remote workers and globally distributed teams to collaborate, while also being able to visualize CAD models in 3D and at full scale. In XR you keep the ability to interact with the model, making it easier to convey ideas and concerns compared to having everybody view it on a screen. As a result, time and money can be saved on travel where previously an in-person meeting would be necessary.

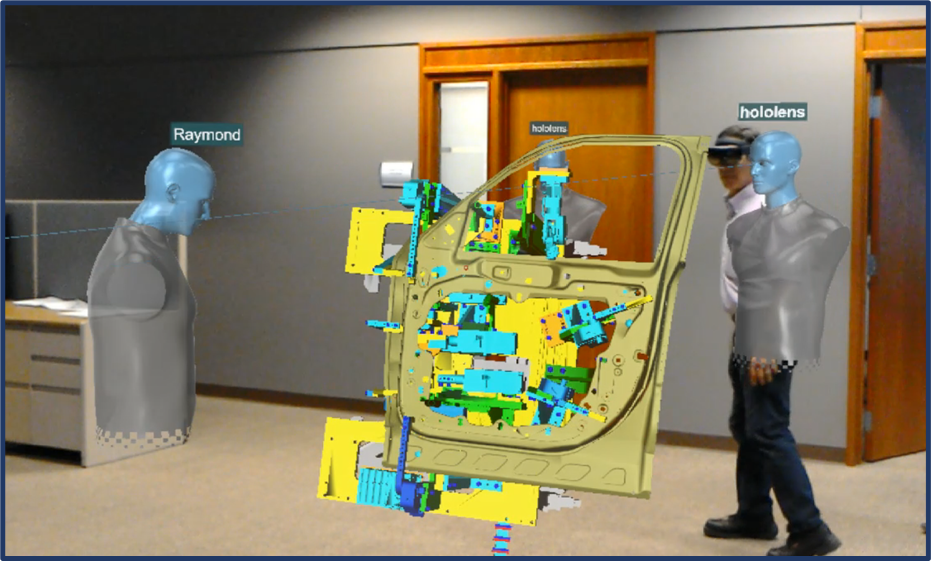

Design reviews are an excellent example of this. The ability to review 3D CAD data at full scale, in a multi-format environment, allows users to conduct design reviews that would previously have required physical early-stage prototyping. The model can be manipulated, and all users can visualize the same model in real time and from their point of view. Additionally, in digital design reviews, specific parts can be isolated and reviewed or the data can be exploded to view each individual part at once. This means that XR can facilitate remote design reviews as well as enhance in-person collaborations.

In-Person Collaboration

XR can also be used when all participants are in the room together. XR makes it easier to understand and contextualize the data compared to just viewing it on a computer. It offers the capability for any user to manipulate the data while everyone views the model at the same time. This visual reference can make it easier to explain concerns and ideas, which results in issues being pointed out and design changes being made earlier in the production process.

Bridging the Communication Gap

Working from home has become a popular option, with the office for national statistics reporting that 40% of working adults did some degree of home working at the beginning of 2023. It was also found that parents of a dependent child were more likely to work from home, suggesting that people who may require more flexibility seek out jobs that offer remote work opportunities.

Remote working comes with many benefits for employees, including an improved work-life balance and spending less time and money commuting. Plus, many people say they are more productive when working from home. However, there can be communication issues when talking solely through a screen. XR can be a huge help in bridging communication gaps and can combine the benefits of in-person and remote work.

The current interest in metaverse technologies is likely influenced by the popularity of remote working. In the future, many aspects of our lives could take place from within the metaverse (an interconnected digital world accessed with VR headsets), from entertainment to shopping to work. Collaboration from multiple locations in XR is the first step towards the realization of the metaverse, giving people a glimpse of what the future could be.

Since XR is fully immersive, there is no feeling of disconnect like there is when interacting with people through a computer screen. In XR everyone can engage with the same data, rather than a single person sharing their screen and controlling what everyone else sees; this can help alleviate confusion when trying to describe a specific aspect of a design. Instead, users can simply show their colleagues themselves. This means that remote work utilizing XR devices and applications can be as interactive as an in-person meeting, making remote working more engaging, closer to in-person meetings, and offers a more viable option for remote collaboration with changes being made in real-time.

Visualizing CAD data in XR can also make your models easier to understand and contextualize. This is particularly important in engineering and manufacturing since it means that issues and potential changes can be spotted earlier in the process; saving money in the long run and ensuring projects are completed efficiently.

TheoremXR

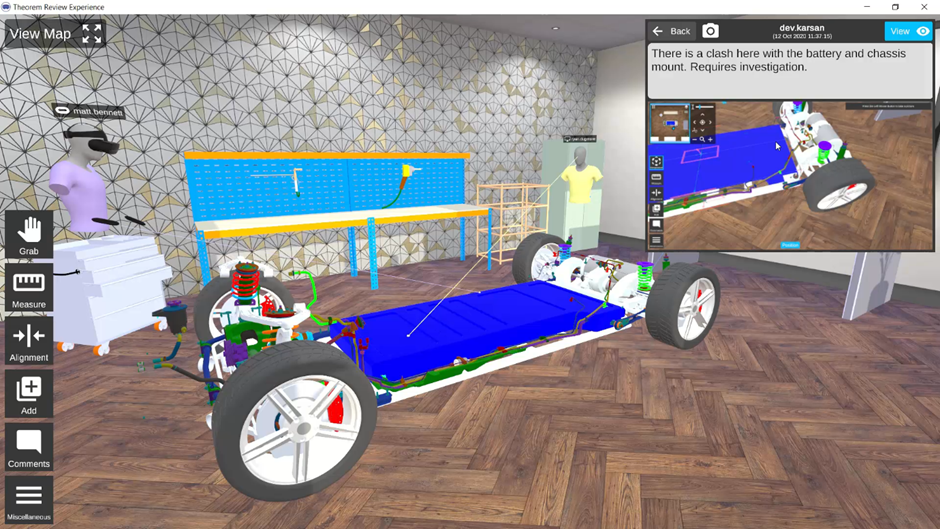

Theorem Solutions offers a range of experiences that can provide XR collaboration capabilities. Included in this is visualization, where multiple users can visualize CAD data in real-time with Mixed Reality and Virtual Reality headsets, although those who don’t have a headset can still join on desktop.

There is also the design review experience which lets users visualize their data at scale and see it in context. It also includes the additional capabilities to annotate, measure, and manipulate the data alongside colleagues. Providing the ability to conduct design reviews completely digitally, without the need to travel to see a physical model.

For factory design use cases, there is also the factory layout experience where a library of CAD models can be uploaded, and a team can design and review a shop floor at full scale. This makes it easier to spot clashes, access issues, and other problems that may otherwise not be immediately obvious.

Valiant TMS Use Cases

Valiant TMS are an excellent example of how using Extended Reality can aid in collaboration. Valiant TMS have been using TheoremXR for a wide range of different use cases and have witnessed first-hand the difference XR can make in connecting teams. Although Valiant TMS had already begun implementing XR, the COVID-19 pandemic was a significant factor in speeding up XR adoption across the business to allow them to continue working in a team environment.

“The multi-user environment design review” and “remote expert” use cases are two significant ways XR was used to bring a team together in a virtual environment for training and design reviews. XR also allowed Valiant TMS to provide support to in-plant maintenance personnel with equipment builds, troubleshooting, and repair. Engineering personnel were able to remotely support in-plant maintenance teams in a way that was more interactive and collaborative. Although these use cases were borne from pandemic requirements, they are still used today as a way of connecting remote team members and teams from multiple countries.

Alongside conducting remote design reviews, Valiant TMS have also been using TheoremXR to train new teams in other countries. By utilizing the virtual environment XR provides, they trained a team in India completely remotely. And since this virtual environment is immersive, they found it much easier to convey important new information and guidance than it would have been with a video call. Additionally, TheoremXR allows users to complete step-by-step process instructions within XR, meaning that training on new machinery, for example, can initially be completed in XR.

Another use case Valiant have found with TheoremXR is the ability to conduct design inspections for tools that are built in a different place to where they were designed. With XR, designers and engineers can collaborate with the build site to review the tools and identify any errors before they are shipped. Building in other countries can help keep costs down while reviewing in XR allows you to maintain the quality.

Valiant TMS have also found that many tasks can be done more efficiently when utilizing XR. With XR there is no need to travel, meaning massive amounts of time can be saved. Plus, it is much easier to organize getting everybody together when everyone can remain in their usual location, resulting in projects having fewer delays.

Final Thoughts

As remote working remains very popular, it’s important to find new ways of collaborating digitally. Remote working comes with many benefits including increased productivity and better work-life balance; however, many people feel like communicating through a screen is not interactive enough.

XR is an excellent solution for engineering and manufacturing companies finding it difficult to communicate effectively with remote workers. It also provides a way to remotely hold meetings that typically have to be done in person, such as reviewing designs which typically need physical prototypes.

Similarly, XR can aid companies who have teams distributed across the world, which is very common in the engineering and manufacturing industries. XR users can interact with their team members in a virtual environment in order to carry out design reviews, attend meetings that are more immersive than simply talking through a screen, and train or guide teams in other locations.

To learn more about XR, contact our team of XR specialists today or request a TheoremXR demo. You can also follow Theorem on LinkedIn for the latest news and tips on using XR in engineering and manufacturing.