With the first month of 2024 now over and the second following suit, it’s time to look towards what the rest of the year may offer in terms of predictions and developments in order to extend the value of your 3D design data through CAD data exchange and collaboration.

In 2024, the landscape for CAD data exchange and collaboration between customers and suppliers will continue to evolve. This is driven by advancements in technology, changing industry demands, and the need for more sustainable and environmentally friendly design and manufacturing processes. Data exchange methods like 3D PDF could help organisations move towards reducing their carbon footprint with the adoption of paperless designs. Along with this the integration/adoption of Augmented, Mixed, and Virtual Reality technologies could aid collaboration in general, as well as reduce the need for travel reducing carbon emissions.

CAD Translation’s Role in Model-Based Definition Practices

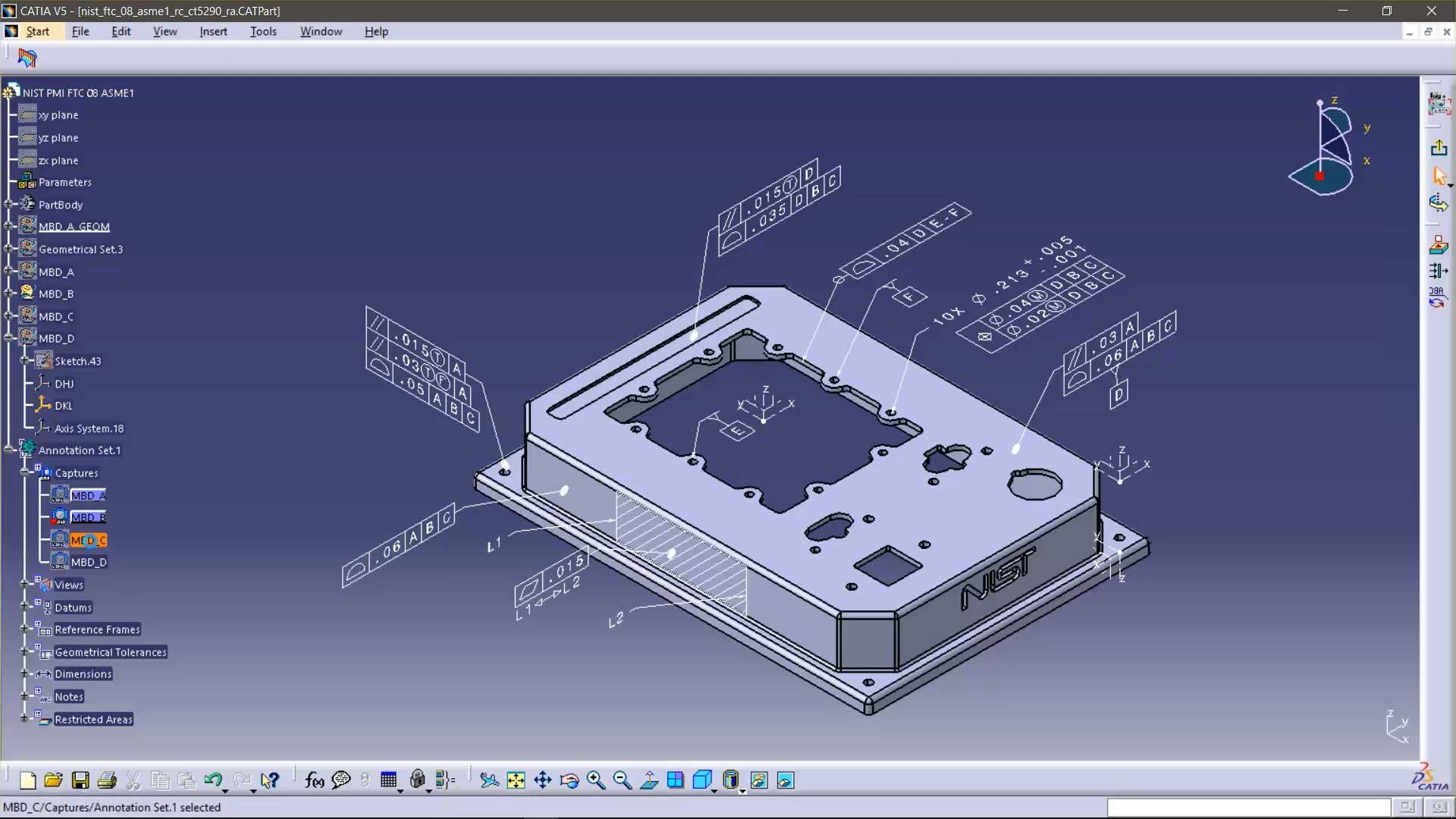

CAD data translation will remain a fundamental aspect of CAD data exchange by enabling interoperability, seamless collaboration, supply chain integration, version control, and compliance with industry standards. CAD data translation tools will continue to be an essential asset for facilitating efficient communication and collaboration in design and engineering projects, delivering a robust, accurate, and secure method of data exchange between customers and suppliers.

Model-Based Definition (MBD) practices include manufacturing information alongside a CAD model. Continued adoption of the MBD approach in the design process will continue to minimize errors, improve communication, and remove ambiguity, ultimately helping to save time and reduce costs around product development. More companies adopting these practices enable better supply chain collaboration; however, because of this it becomes more important that CAD translation tools support these MBD practices allowing this data to be shared throughout the supply chain.

Sustainability in Engineering and Manufacturing

Sustainability has been an important consideration in engineering and manufacturing for many years, with companies actively looking to reduce carbon emissions and minimize waste. We will continue to see businesses improving their manufacturing processes, looking at ways to expand sustainable practices into other areas of the business.

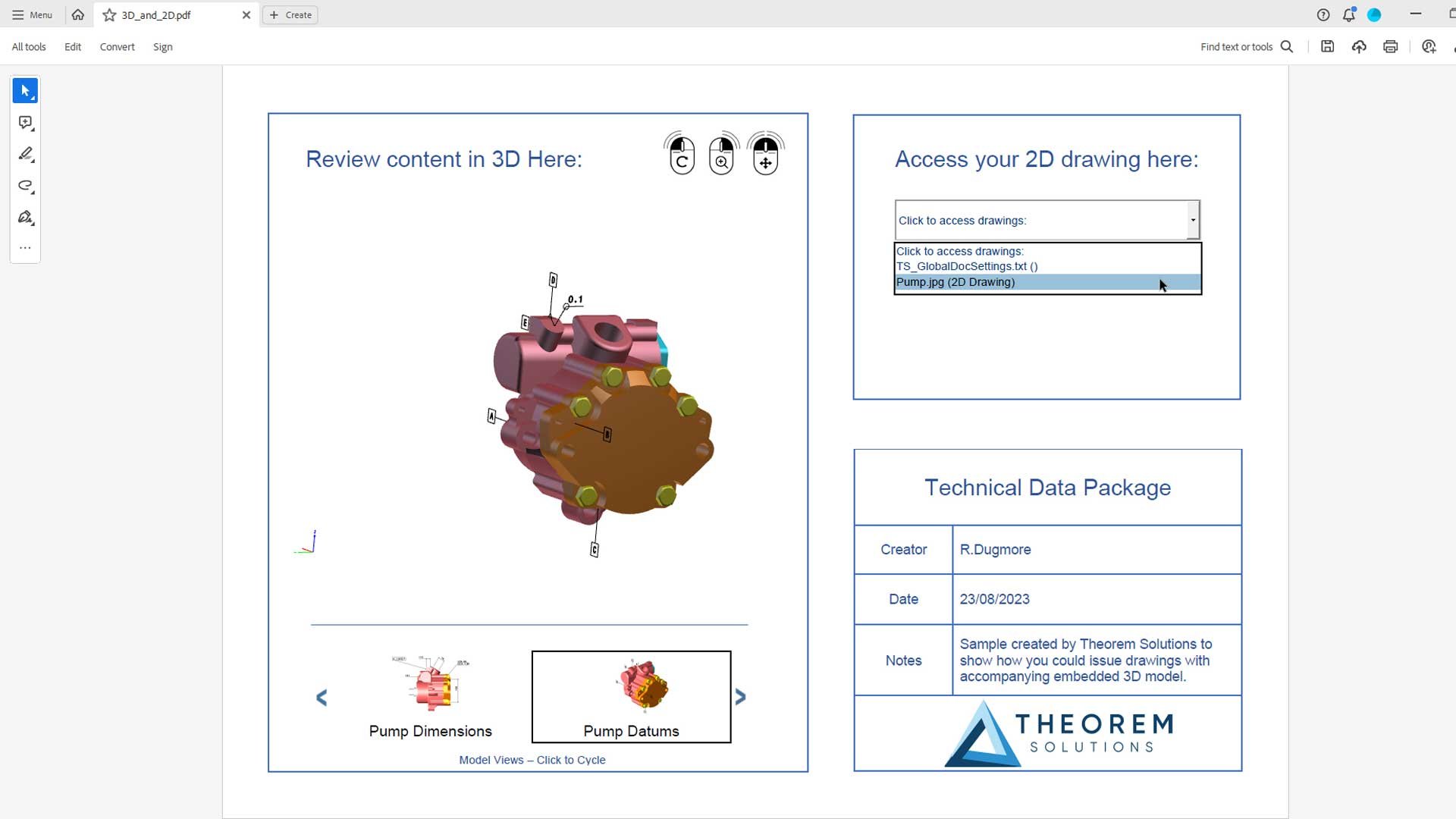

The use of the interactive 3D PDF format will continue to grow throughout 2024 and into 2025 as organisations look to implement paper-free design processes. Despite the popularity of using CAD applications for 3D designs, many companies still use paper 2D drawings to communicate design intent.

The 3D PDF format will continue to revolutionise the data exchange process as it makes CAD data accessible to non-CAD users, in a standards-based, freely available format that is helping to secure IP. These 3D PDFs can also include digital 2D drawings attached to the document, meaning they can be used to share all the required design data and information in a completely paperless process. Templates can make this process even more effective by allowing documents to be customized based on the specific information users need to include.

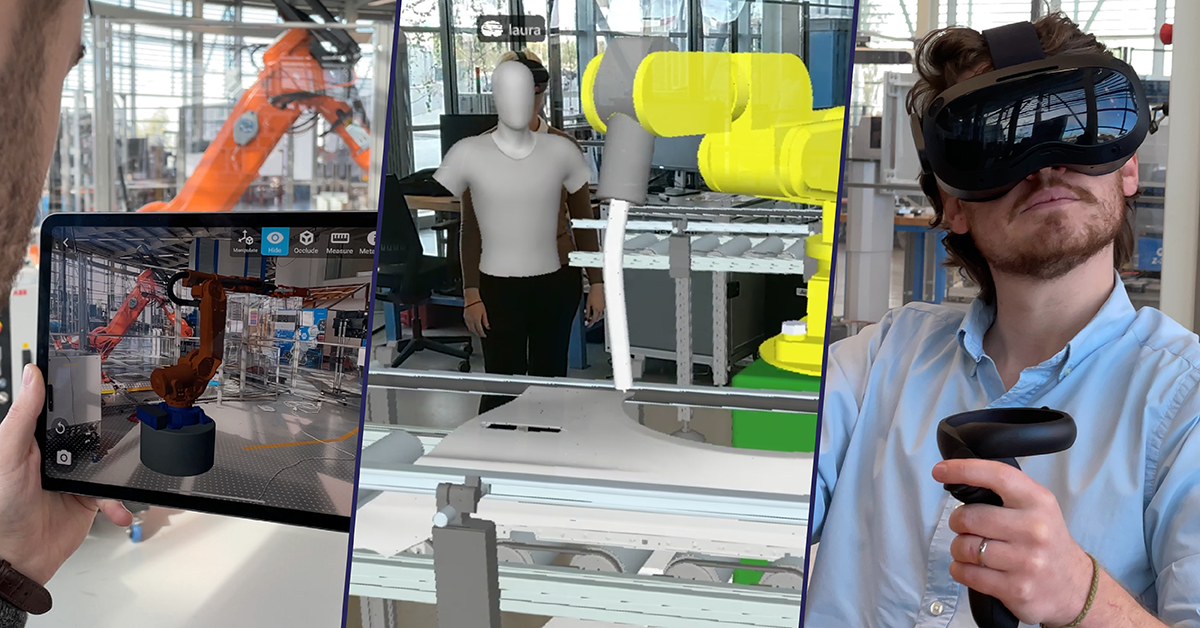

Another powerful tool for improving sustainability in engineering and manufacturing is Extended Reality (XR). With the introduction, integration, and adoption of Augmented (AR), Mixed (MR), and Virtual Reality (VR)(collectively known as Extended Reality) to collaboratively visualize design data at scale and in-context, organisations can deliver a more sustainable product. XR reduces waste by removing the need for early-stage prototyping, allows users to highlight design errors sooner in the process, and removes the requirement for unnecessary travel through remote collaboration.

XR Technology With New Capabilities

2024 will see greater adoption of XR technologies, both from a software and hardware perspective, as organisations look to start their journeys into the industrial metaverse or build upon their current deployment. The recent release of the Meta Quest 3 in October 2023 and the Apple Vision Pro even more recently (released on the 2nd of February 2024 in the USA) will open up new opportunities to visualize and collaborate around design data through new functionality, rendering capabilities, and collaboration.

Typically, device type dictates the intended use case, with Mixed Reality (MR) devices and Virtual Reality (VR) devices offering different capabilities. However, these new headsets combine the benefits of MR (overlaying the real world with data) and VR (a fully immersive digital environment) by allowing users to switch between virtual and physical environments. As a result, companies can do more with a single device, and benefit from experiences designed for both MR and VR.

Along with this, many XR devices now have 5G capabilities. As a result, XR is more broadly adaptable to a wide range of use cases and scenarios since the devices won’t need to be permanently connected to the network. This likely means that the coming year will see an increase in XR adoption as companies discover new ways for it to be used.

The requirement for accurate data preparation, optimisation, and processing will become more vital than ever before. With so many people looking to XR as a means to collaborate and work in real-time, data needs to be quickly available in a usable format that is supported by the device and meets the needs of evolving use cases.

XR for Marketing

Extended Reality may seem like a new trend, but many companies have already adopted XR solutions for a wide range of use cases from collaborative design reviews to factory layout designing. However, one emerging use case for XR is utilizing its immersive visualization capabilities for engineering-based marketing.

With XR, customers can see full-scale models of products without needing a physical model. In many cases, XR is much more portable than the product, so when seeing customers in person or exhibiting at events XR can let you bring your products along. Alternatively, by including QR codes linked to your models in brochures or on your website customers could view these models in their own time, using augmented reality applications.

Training in XR

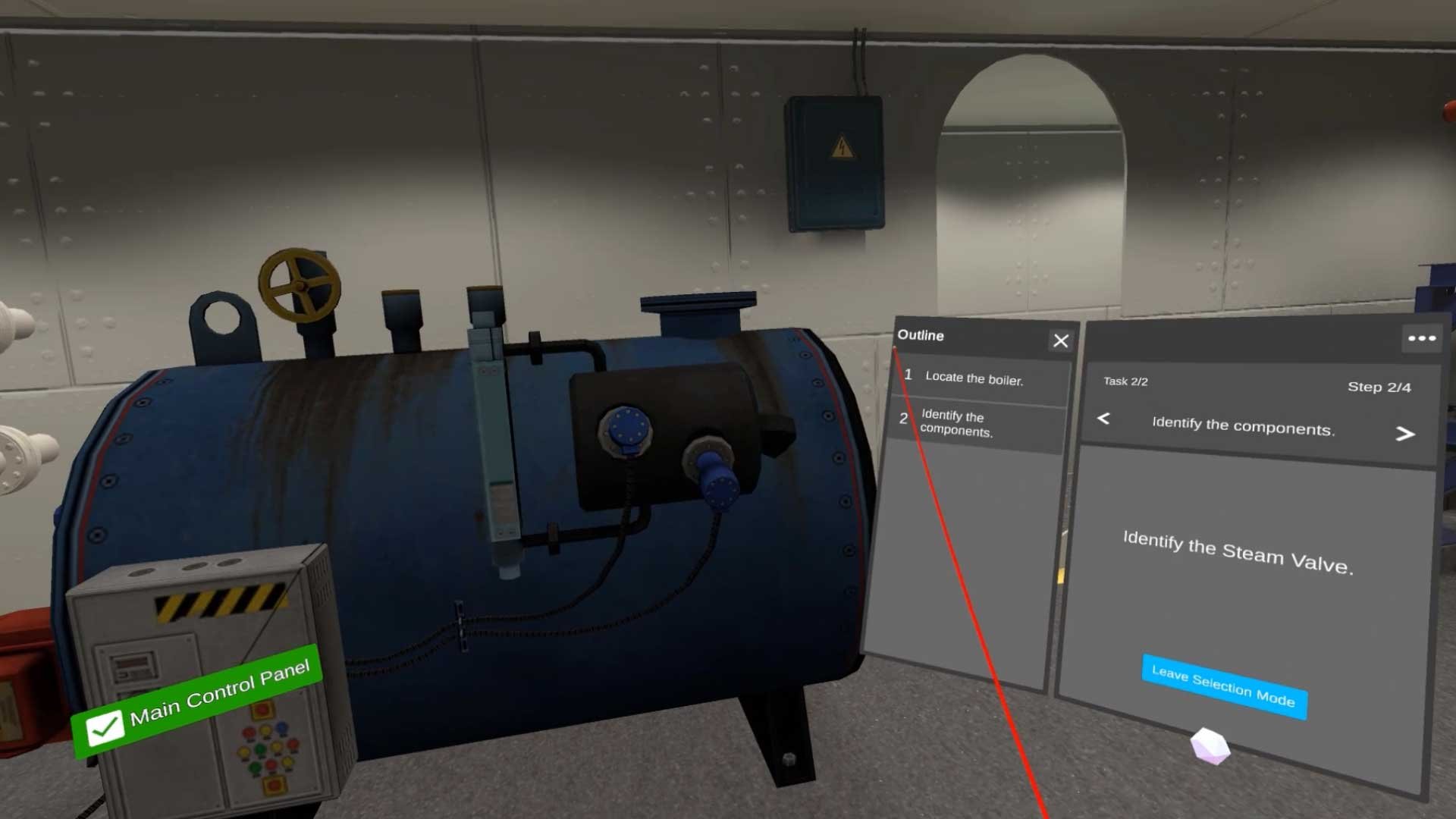

Another area that XR can enhance is training and given the benefits it’s likely many more engineering and manufacturing companies will be utilizing XR for training in the near future. XR can provide an immersive environment, which typically results in users learning faster and retaining the information better.

Additionally, XR can allow for training in scenarios that would typically be dangerous, this means that users can learn in a safe environment while still benefiting from hands-on experience. Similarly, there are many situations where hands-on experience isn’t viable, for example, training on a machine that would need to be shut down which would be very costly. In this case, XR can be used for the initial training, reducing the impact.

In Summary

Engineering and manufacturing is an industry that is always evolving, and new trends are sure to arise, while many older ideas will continue to be pushed to the forefront as is the case with MBD. Sustainability is also a continuing focus of the industry that is sure to see some attention in the coming year with 3D PDF and XR providing innovative solutions for developing sustainable practices in other areas of the manufacturing process. Finally, XR continues to intrigue many in the industry, and as more use cases are considered large-scale adoption becomes more likely.

For more information about CAD Translation, 3D PDF and XR technology, contact Theorem today. You can also follow Theorem on LinkedIn for the latest news and tips on CAD data exchange.