Model-Based Definition

Theorem provide solutions to enable you to share your MBD content between CAD systems and CAD and lightweight Visualization systems. Enabling you to collaborate with your customers and suppliers.

Understanding Model-based Definition

Model-based definition (MBD) is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define the manufacturing data that is needed to make individual components and product assemblies. The types of information included are Geometric Dimensioning and Tolerancing (GD&T) data, component level materials, assembly level bills of materials, etc. By contrast, other methodologies have historically required accompanying use of 2D engineering drawings to provide such details.

Modern 3D CAD applications allow for the insertion of engineering information such as dimensions, GD&T, notes and other product details within the 3D digital data set for components and assemblies. MBD uses such capabilities to establish the 3D digital data set as the source of these specifications and design authority for the product. The 3D digital data set may contain enough information to manufacture and inspect product without the need for engineering drawings (which have traditionally contained such information).

Use of information from a rich 3D digital data set allows for rapid prototyping of product via various processes, such as 3D printing. A manufacturer may be able to feed 3D digital data directly to manufacturing devices such as CNC machines and to CMM machines for inspection.

Implementing MBD at the beginning of the product lifecycle and re-using it throughout an organisation and its supply chain enables quick, seamless and cost-effective development and delivery of products.

MBD and the Data Exchange Challenge

The requirement to share 3D CAD data, containing MBD content, where incompatible CAD systems (or incompatible CAD and lightweight viewing systems) exists, creates a data translation challenge.

For model-based definition to be effective within large organizations and smaller organizations in the supply chain there is considerable demand for data translation between CAD systems and lightweight formats. Not just data translation but data translation that can deliver product manufacturing information to the point of need.

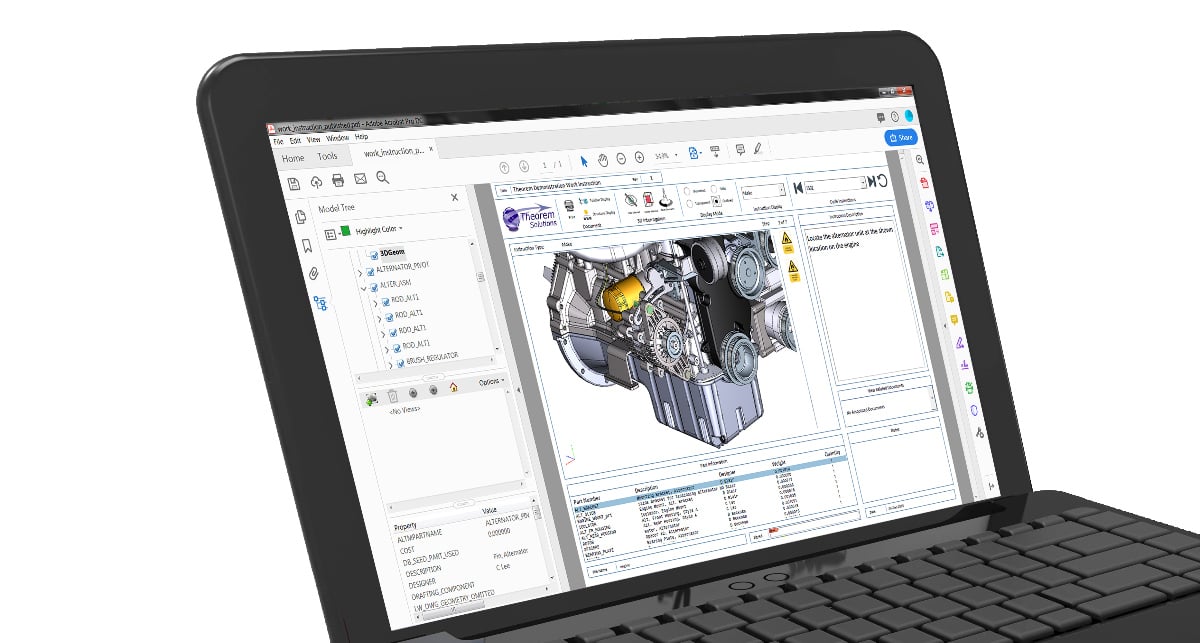

Theorem’s CADTranslate, CADPublish and TheoremXR products support MBD, enabling design and manufacturing to co-exist by efficiently translating data in to a variety of systems. The solutions enable specific views to be filtered and processed and enable lightweight viewer applications to save views and sections, and interrogate, annotate and share data.

Utilizing Model-based Definition in Manufacturing

If the manufacturing department has the same CAD system as the design department then moving files containing MBD data is straightforward. However, if the departments have different CAD systems then moving the data becomes a problem. Even when both departments have the same CAD systems the cost of CAD (MBD) licenses can be expensive and so the use of lightweight viewers can reduce the cost of CAD licenses and data storage costs. There are a number of lightweight viewing formats available: 3D PDF, 3D XML, CreoView and JT. However, if the lightweight viewing format is not from the CAD vendor then data incompatibility is still a problem.

Everything you need to know about the portable document format (PDF)

Of course, you know what a PDF file is, right? It’s a document that has been converted from something like Microsoft Word or PowerPoint so that its contents can be shared by the author; that’s it, isn’t it? Well no actually; it’s quite a bit more than that.

Catchup on the Latest CADPublish News

Evaluation Request

Register now to request your free evaluation license of the Theorem CADPublish solution.

In just a few simple steps we will be able to validate your request based upon the details you provide.

- Complete all of the required details

- Which product you are requesting an evaluation for

- We will contact you to discuss your requirements

- Please only use your company email address for validation purposes as we will not respond to personal email accounts