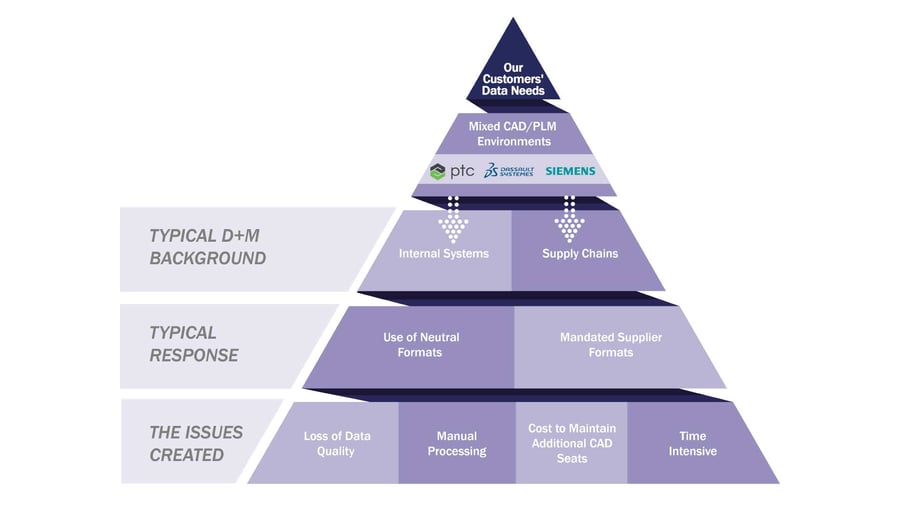

Engineering and manufacturing companies are often working in an environment that involves multiple CAD and PLM systems, meaning that you may be exchanging data (sending and/or receiving) with someone internally within your organization, or as a part of your supply chain, who works with a different CAD application to yourself.

Typically, there are two ways to solve this problem: either using a neutral format, such as STEP or IGES, that can be used in multiple CAD systems, or by changing the CAD system used to match the mandated supplier format. However, both of these options come with issues and also associated costs.

The Issues of Data Exchange

There is a risk of data degradation when using neutral formats which could lead to data losing accuracy. Depending upon what the data is being used for, this could mean that the end result is unusable due to a reduction in geometry quality, tolerance issues, a loss of colours and textures, and also a loss of metadata. Along with this, converting into a neutral format is usually a manual process, so this method can be time-consuming particularly when converting a large amount of data. To add to this, you may need to spend additional time with a validation process to verify how successful the translation output is.

However, switching to a mandated supplier format isn’t as simple as it may sound. Purchasing and maintaining a new CAD system can be extremely costly. Plus, having to train existing users in new software will cost valuable time, resources, and also money, which can increase project costs and overheads exponentially. Both of these problems are amplified if you are working in a supply chain that has multiple mandated supplier formats since you would need to switch between multiple CAD systems, potentially doubling or tripling costs, and introducing a number of additional steps into your design process.

How Can a Direct Translator Help?

Using a direct translator can effectively help to resolve these problems. A direct translator converts data from one CAD system into a different CAD system; this is a one-step process that results in a fast translation. Each time data is converted there is a chance of data loss, so this one-step process ensures greater accuracy and a more robust translation than can be expected by converting into a neutral format. Additionally, direct translators may allow for batch processing, allowing large volumes of data to be translated easily without requiring manual input. This is much more feasible and far less time-intensive than manually converting high volumes of data into neutral formats.

Direct translators are easy to use, which can save time that would need to be spent on training. This could also potentially bring significant cost savings compared to purchasing and maintaining multiple licenses of a different CAD system. By utilizing a direct translator, which can be installed locally or on a server and used by multiple users, you can cut down on the number of CAD licenses needed, reducing IT overheads.

Another significant benefit of using a direct translator is the fact that it supports Model Based Definition (MBD). MBD is the practice of including all the necessary information required to define a product alongside your CAD model, effectively ensuring that all the data required is available in one place. With a direct translator Product Manufacturing Information (PMI) and Geometric Dimensioning and Tolerancing (GDT) is brought through from your original CAD system.

Theorem Solutions’ CADTranslate Translators

Theorem Solutions has over 30 years of experience of working with design data and are experts in CAD translation, trusted by a wide range of engineering and manufacturing companies globally. Since Theorem is partnered with all the major CAD suppliers, their translators utilize vendor APIs without needing to reverse engineer the native CAD software which may result in a less accurate output that doesn’t give the desired results. This can result in a higher degree of accuracy, as well as ensuring a quick translation process. Along with this, when CAD software is updated to a new revision Theorem develops their software against the new libraries, allowing the translators to quickly support the latest revisions.

This makes Theorem’s CADTranslate an excellent option for users who need a non-parametric translation, focusing on 3D models rather than 2D drawings. Features and history are not supported, however, assembly structure, surfaces, colours, and attribute data, as well as Product Manufacturing Information (GD&T), are all brought through from the original CAD data using a Theorem translator.

In Summary

Multi-CAD environments are a common occurrence within engineering and manufacturing, with many points within a supply chain working with different types of CAD systems. However, utilizing neutral formats or switching to a supplier mandated format, which are typical solutions to the problem, come with their own issues. With a direct translator, users can save time and money with a fast and accurate one-step translation between CAD formats. Also, with automated translations and batch processing a lot of time can be saved compared to manual processes. Direct translators are easy to use and can address many of the problems that occur when working with partners and suppliers that require data in a different CAD format.

For more information about CAD data exchange, explore our CADTranslate products or get in touch with our team of CAD specialists today. You can also follow Theorem on LinkedIn for the latest news and insights.