A Guide to 3D PDF

01 - Introduction

There are a couple of tools that feature in the CADPublish family, however, this post is focussed on PDF. Of course, you know what a PDF file is, right? It’s a document that has been converted from something like Microsoft Word or PowerPoint so that its contents can be shared by the author; that’s it, isn’t it? Well no actually; it’s quite a bit more than that.

The Portable Document Format (PDF) is a file format developed by Adobe in the 1990s to present documents, including text formatting and images, in a manner independent of application software, hardware, and operating systems. Each PDF file encapsulates a complete description of a fixed-layout flat document, including the text, fonts, vector graphics, raster images and other information needed to display it. PDF was standardized as an open format, ISO 32000, in 2008.

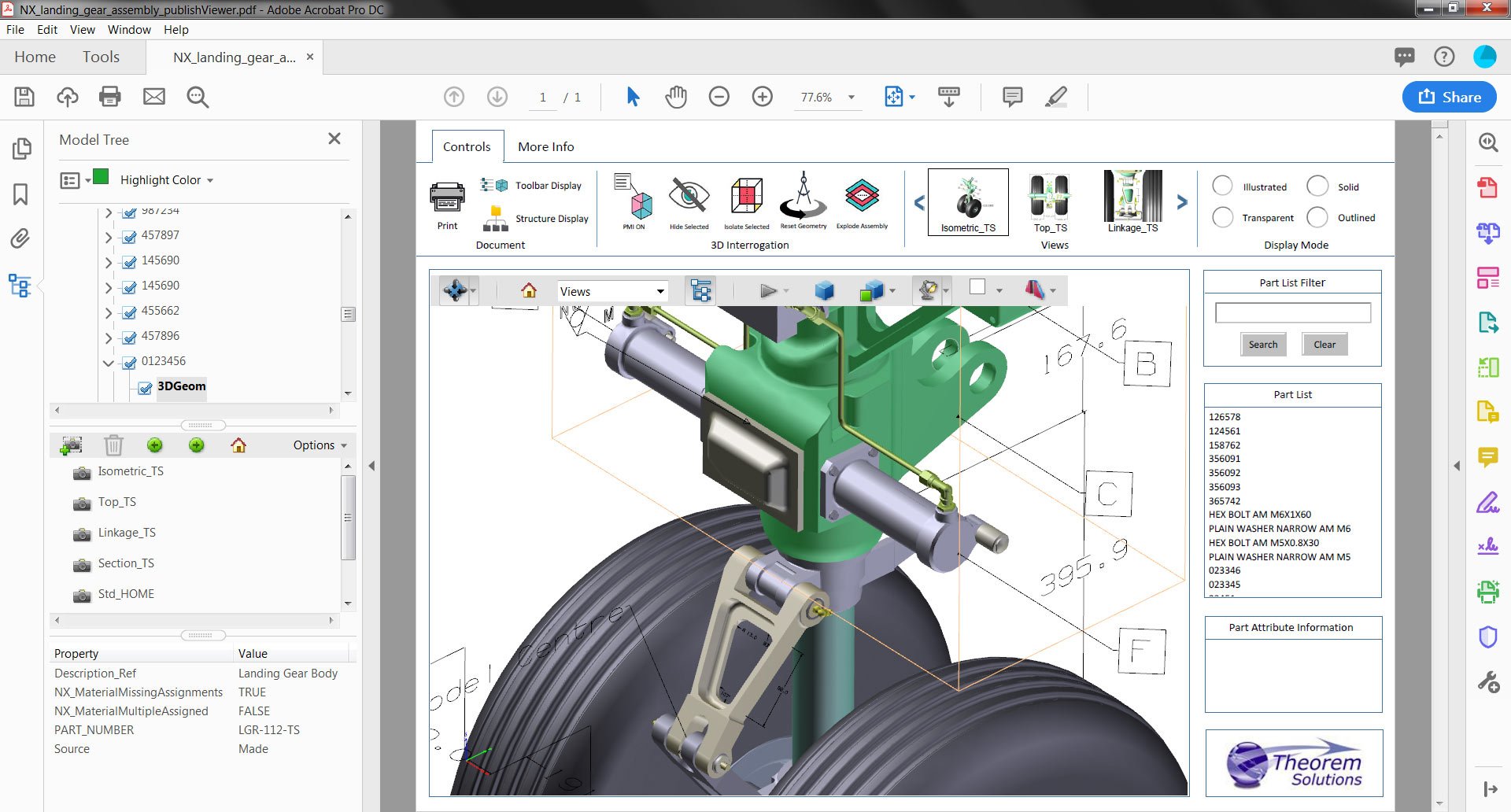

Today, PDF files may contain a variety of content besides flat text and graphics including logical structuring elements, interactive elements such as annotations and form-fields, layers, rich media (including video content) and three-dimensional objects. The PDF specification also provides for encryption and digital signatures, file attachments and metadata to enable workflows requiring these features. It is the three-dimensional objects element that we are most interested in, for the purposes of this document, anyway.

If you’re unaware of 3D PDF, then you would be forgiven for assuming that the 3D content would be a static image, or maybe an object that could rotate, much like a GIF. In fact, the reality and the power of the 3D PDF are truly extraordinary.

In order to fully appreciate this, I suggest that you try one. Here is a sample 3D PDF file.

The best way to describe what you can now see is that this is CAD inside a Document; almost like the PDF document is a wrapper hiding a far more powerful product inside!

02 - Who is CADPublish designed for?

With a new era of intelligent documentation and information exchange utilizing 3D PDFs emerging, CADPublish is an enabling tool for anyone who needs to be involved in the process so they can read, view and mark-up 3D data, thus speeding up the development process to leverage investments in CAD and PLM data assets. This allows those within the organization and supply chain to view, interrogate and contribute to the creative process and importantly, in an increasingly competitive marketplace, gain a strategic advantage.

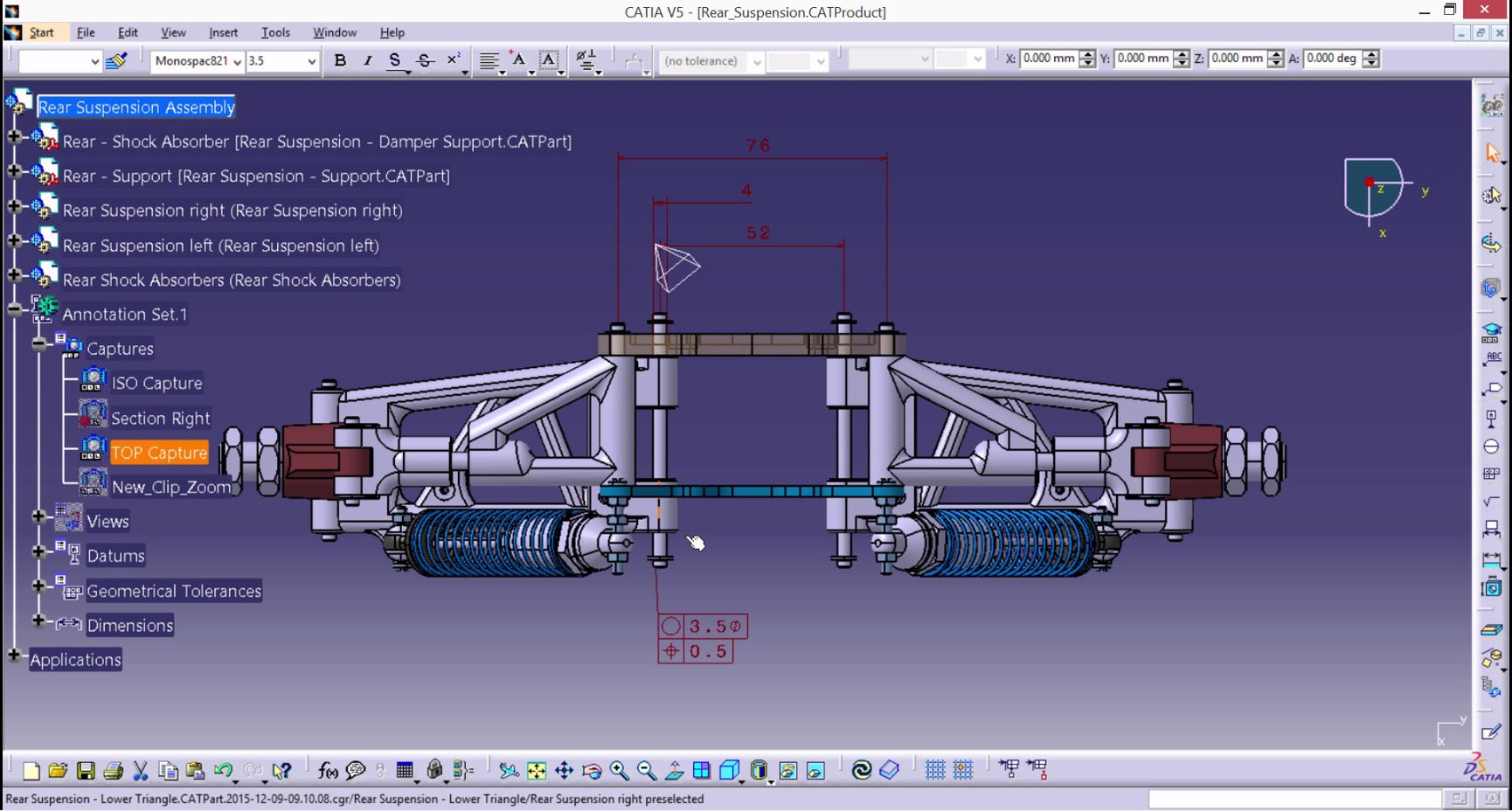

CADPublish enables organizations who design with CATIA V5, CATIA 3DEXPERIENCE, Creo or NX, or who want to collaborate in 3D model in via the world of PDF. Using PDF improves security when collaborating with business partners. PDF secures the data by providing password protection to the document, protecting your intellectual property. Publish 3D makes sure that outside of the enterprise, your data is secure.

CADPublish is scalable, it provides a simple save as tool, up to a full enterprise high volume publishing solution, enabling collaborative teams to quickly and easily create documentation containing interactive 3D data published directly from native CAD or PLM.

03 - How can CADPublish be of benefit?

The beauty of this technology is the simplicity of deployment and ease of use, removing the barriers to integrating departments, customers and suppliers into the product lifecycle process.

Imagine the scenario where everyone in the organization and the supply chain can view, interrogate and contribute to the creative process.

The opportunity for gaining a strategic advantage by adopting this new technology to leverage your CAD and PLM assets should not be underestimated.

04 - Why use interactive 3DPDFs?

Published interactive 3D data contained within a 3D PDF file can be shared, viewed and interrogated using the freely available Adobe Acrobat Reader by users and departments who do not have access to native CAD data, but who need a 3D representation without the need for additional installed applications and knowledge of how they work. Once published, using Adobe Acrobat Reader a user will be able to:

- View the 3D model

- Interrogate the model tree sub-assemblies

- Turn components in assemblies on and off

- Shade and render for technical authoring

- View as a solid and wireframe

- Cross section components and assemblies

A 3D PDF document is extremely lightweight and therefore easily emailed without the danger of it being blocked by a firewall or inbox capacity. Intellectual Property can also be exchanged in a PDF protecting the native data. A smarter way of exchanging your design data. Publish 3D can be configured to distribute CAD models in many different contexts for different departments (all in one process), e.g.

- As a solid assembly (rendered) for marketing

- Hidden line removed for technical publication

- An exploded view for customer service

- Part of a bill of materials for purchasing

CADPublish will run the process at the press of a button (or as part of an overnight batch process) and will create multiple documents for multiple users. It can also email the data exchange document or can upload it to an FTP site or the cloud.

In addition to the 3D model itself, there are many user-configurable features that lend themselves to an array of use cases.

05 - Documentation

So, we have been able to ascertain that CADPublish enables the publishing of 3D CAD and visualization data directly from within design applications into interactive 3D PDF documents. The published document output contains embedded interactive 3D representations of the native CAD data (within a pre-defined template).

These documents can be annotated and additional rich media such as PowerPoint files, video, hyperlinks to additional online information, and spreadsheet data can be auto-embedded or inserted manually. The PDF can also act like a .zip file to transport additional files, for example, native CAD data, purchasing documentation or statistical process control documentation.

Using CADPublish enables you to create a range of interactive documentation including:

- Works Instruction

- Request for Quotation for Purchasing Departments

- Technical Data Sheet

- Technical Data Package – Archiving

- Technical publications:

- Inspection Reports for Quality and Inspection Departments

- Engineering Change Request for Engineering Departments

- Bill of Materials (BOM) for Manufacturing Departments

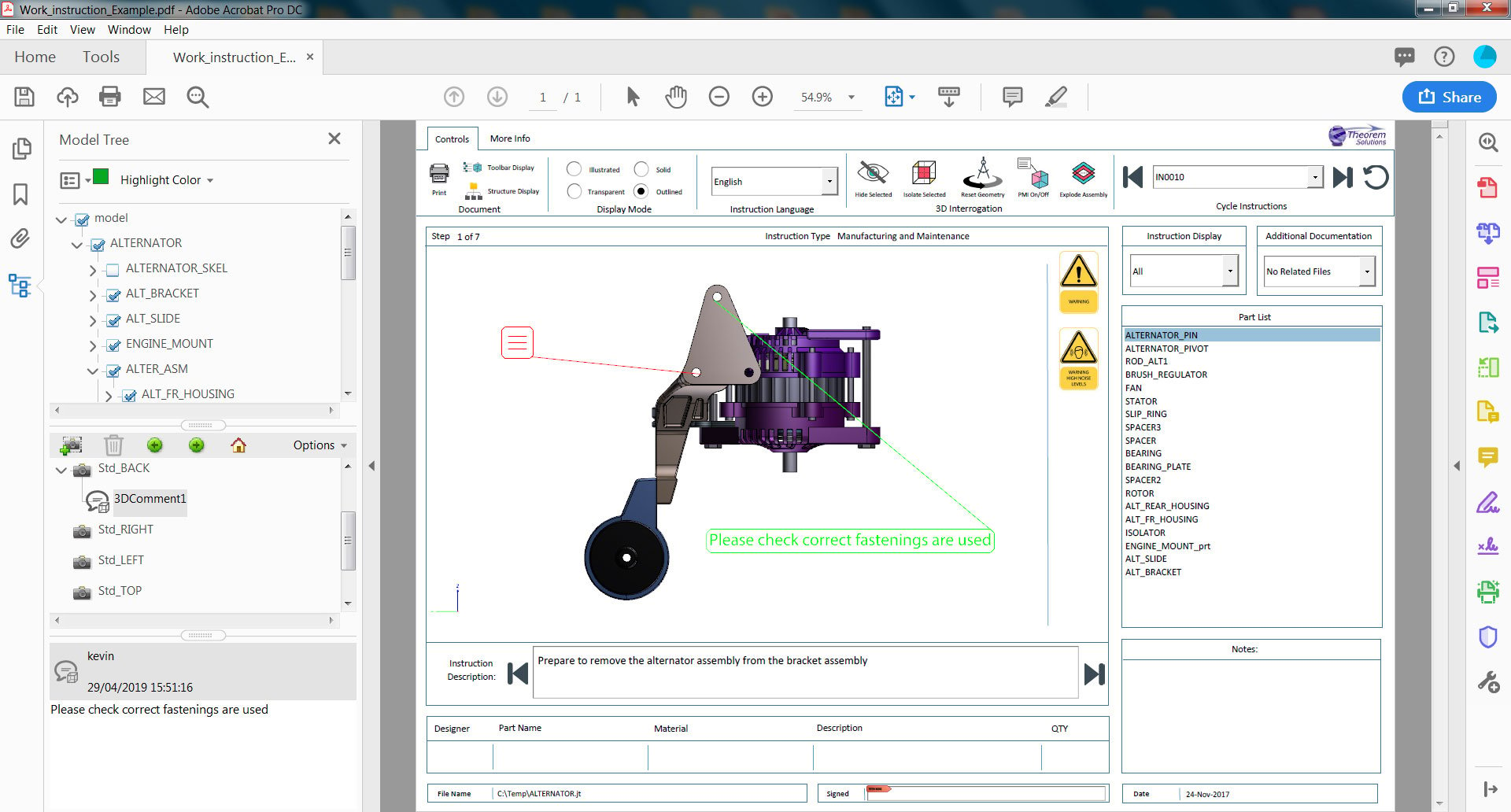

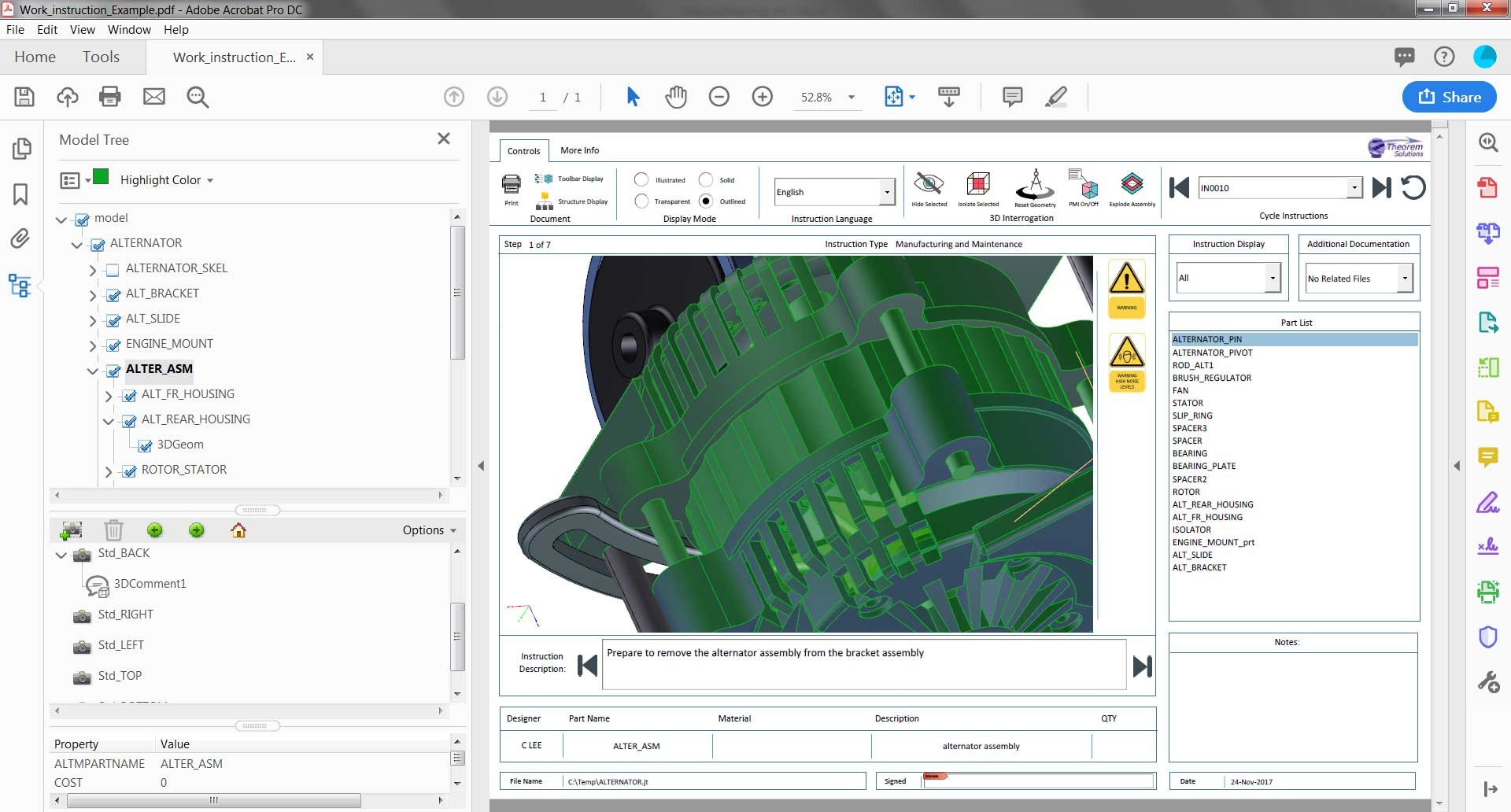

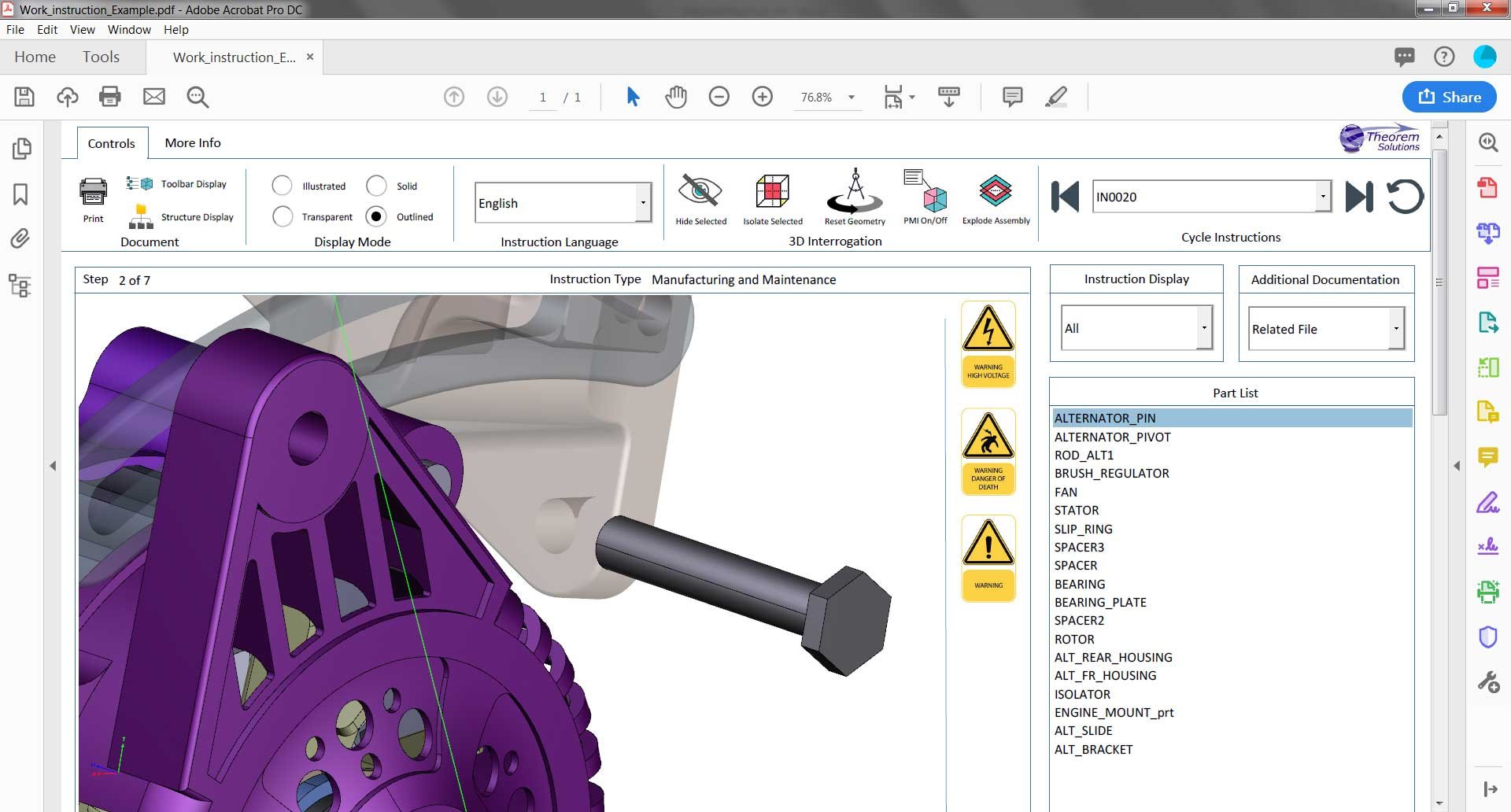

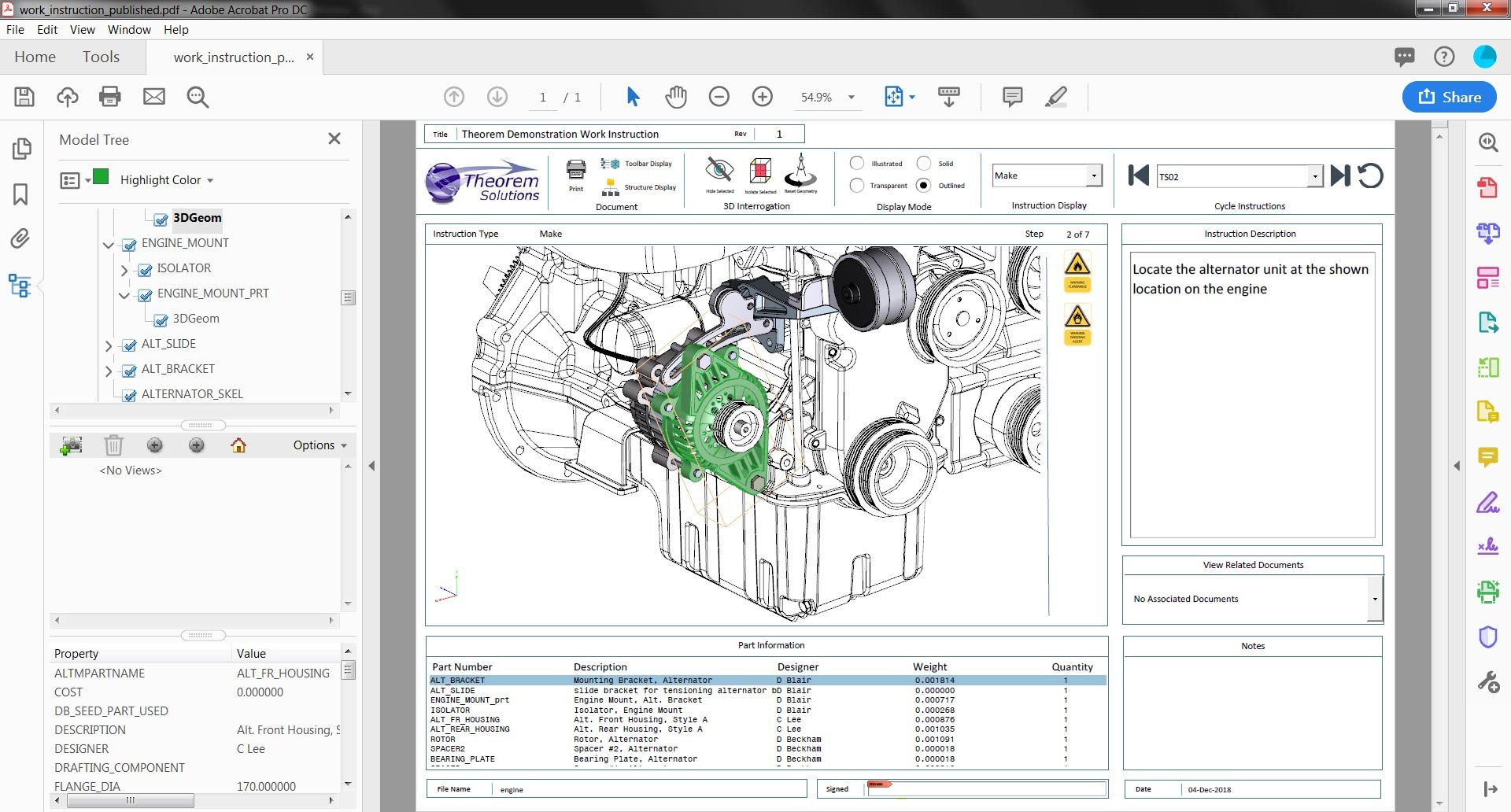

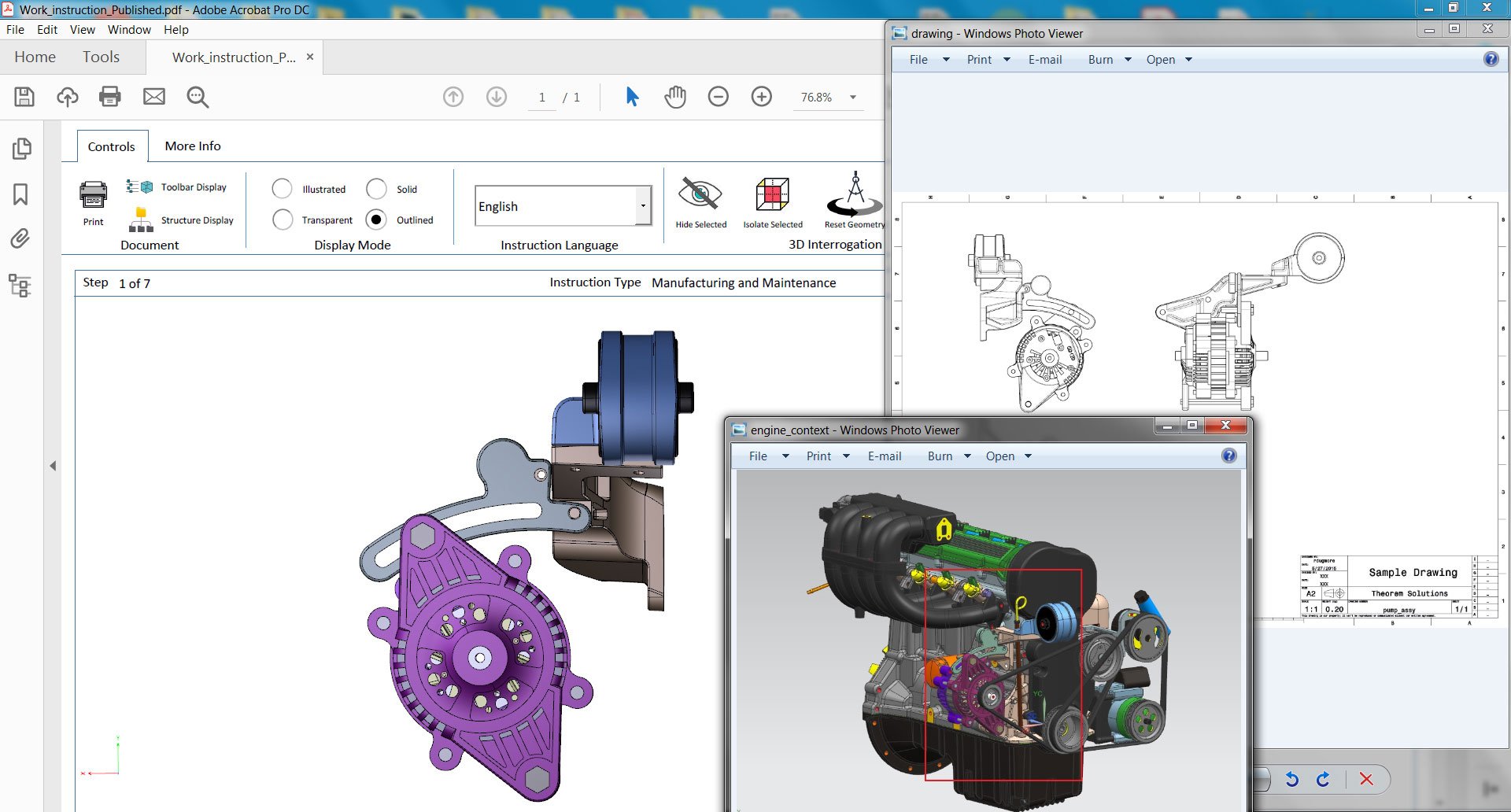

06 - Works Instruction

A complex, yet comprehensive approach to using the PDF format enabling interactive, step by step building capabilities for manufacturing in a single document.

The Works Instruction document in its simplest form can contain:

- A stepped process; each step referencing its own unique data set and view

- A 3D section showing an interactive representation of filtered geometry

- Accompanying icons which help to reduce ambiguity where the language is an issue when needing to highlight specific requirements – i.e. hazardous area.

- A means to show information alongside the 3D representation

- The instructions for each process step.

- Multi-lingual content to suit the audience based on geographical location

- Process stages can contain filtered steps, based upon user permissions or required actions.

- Additional Documentation can be attached to give context and clarity for defined operation states; each step can contain its own attached data set.

The Works Instruction template environment takes the capabilities of the 3D PDF format to the next level for sharing and consuming data.

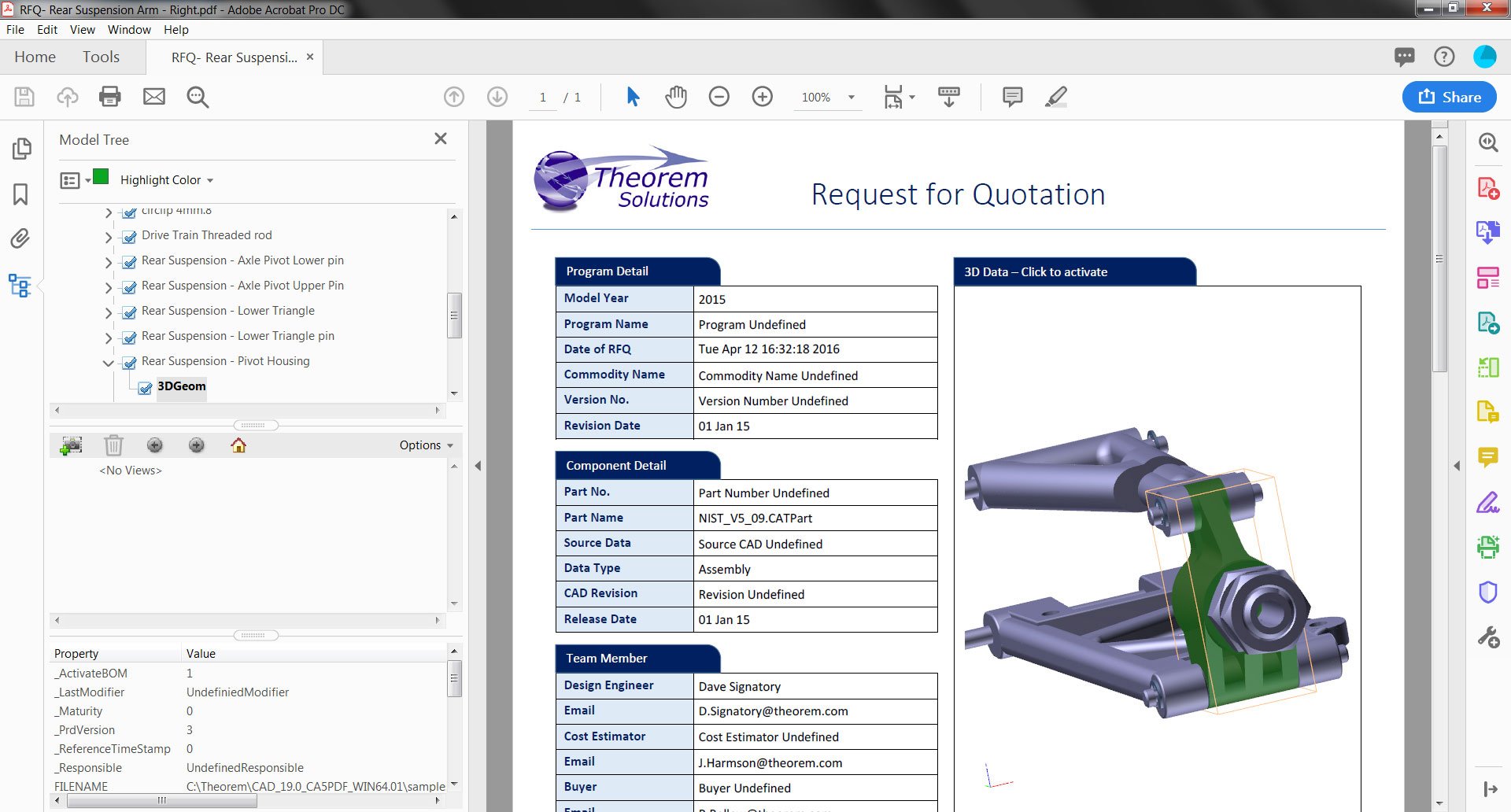

07 - Request for Quotation for Purchasing Departments

3D PDF for Purchasing departments offers the ability to present suppliers with crystal clear interactive 3D representations of products, components, sub-assemblies and specifications; removing ambiguity from the procurement process. The fully interactive three dimensional and two-dimensional elevation views empower purchasing departments to easily create and share RFQ documents, containing pre-populated forms and interactive 3D data published directly from native CAD data held on PLM systems.

An RFQ in its simplest form can contain:

- Costing information

- Material Information

- Technical specifications

- Briefing notes and care points

- Interactive 3D geometry

08 - Technical Data Sheet

Using the 3D PDF format to represent a Technical data sheet is revolutionizing how easily data can be gathered, displayed and interacted with. By incorporating the traditional characteristics of a technical data sheet within a 3D PDF document template as part of the creation process, the output and uses are dramatically enhanced.

A Technical Data Sheet traditionally summarizes the performance and other technical characteristics of a product, machine, component, material, etc. in sufficient detail that allows design engineers, for example, to understand the role of the ‘component’ within the overall design of the product. They generally have a very formal, yet static 2D layout which has been pulled together manually from disparate sources.

It is now possible to publish a single document containing a combination of data from a variety of sources, alongside an interactive representation of a 3D component, which is bringing new clarity to the technical detail and configuration specifications.

Highlighting a component and being able to instantly see where it fits into the overall product assembly, costings, materials, etc. is bringing a new dimension to the traditional technical data sheet.

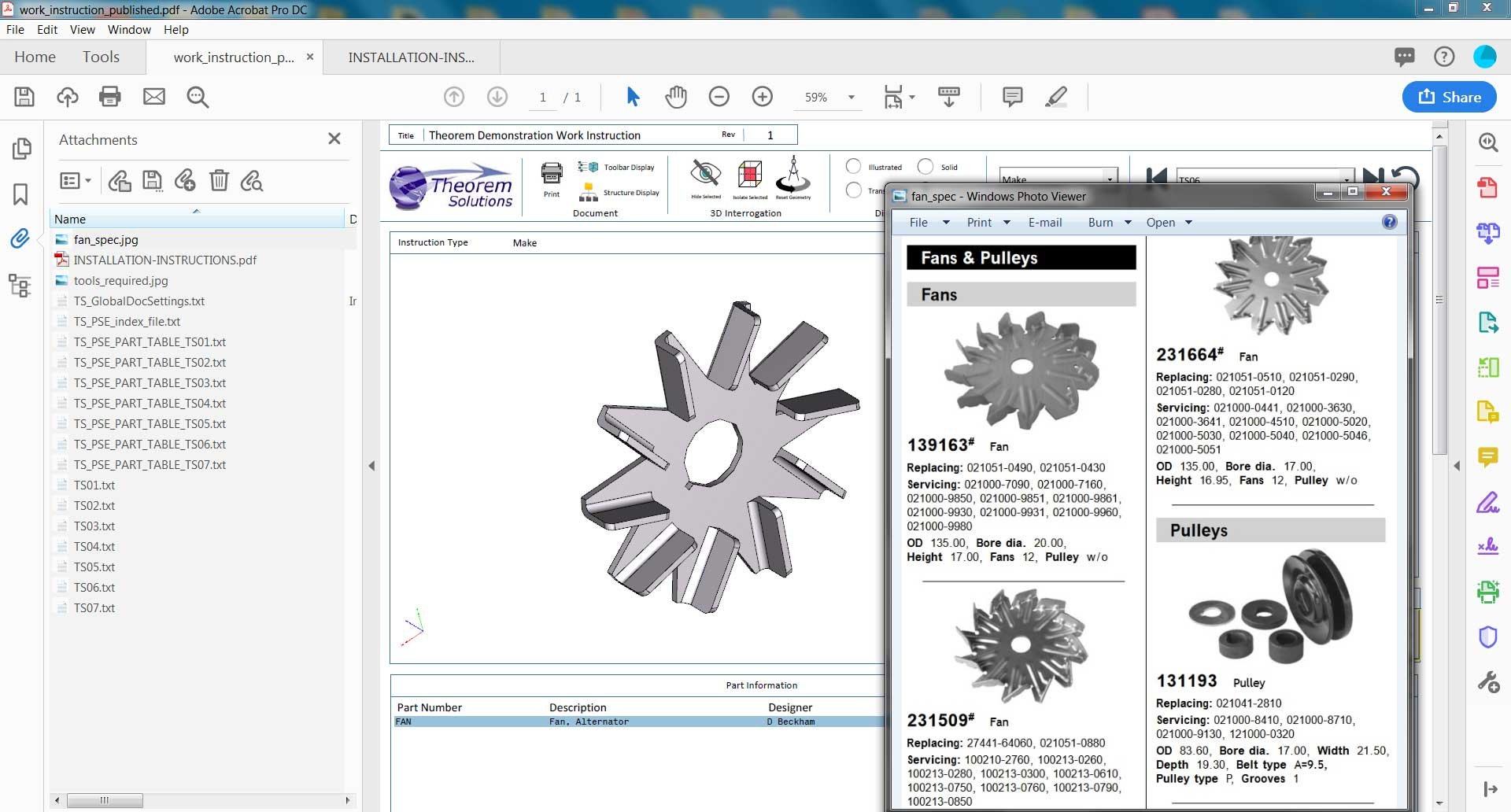

09 - Technical Data Package- Archiving

Being able to attach files to a standard PDF file immediately changes how it can be utilized within a business. Suddenly, what was a document, can be classed as a rich in content, technical data package that can be used for archiving.

You can attach Jpegs, Spreadsheets, and Drawings, Movies or even native CAD and Visualization files! Attachments can be launched directly from within the PDF helping to give context and clarity, and using Adobe’s built-in compression engine, the ‘package’ remains a portable format that is still easily emailed, unlike ZIP and RAR type packages that can get be blocked by an organization due to potential security risks.

With the addition of password protection and digital rights management (DRM) for added security, 3D PDF is a very rich and easy way to communicate and consume data up and down any supply chain as well as archive complete project and design data in a single secure document.

10 - Technical Publications

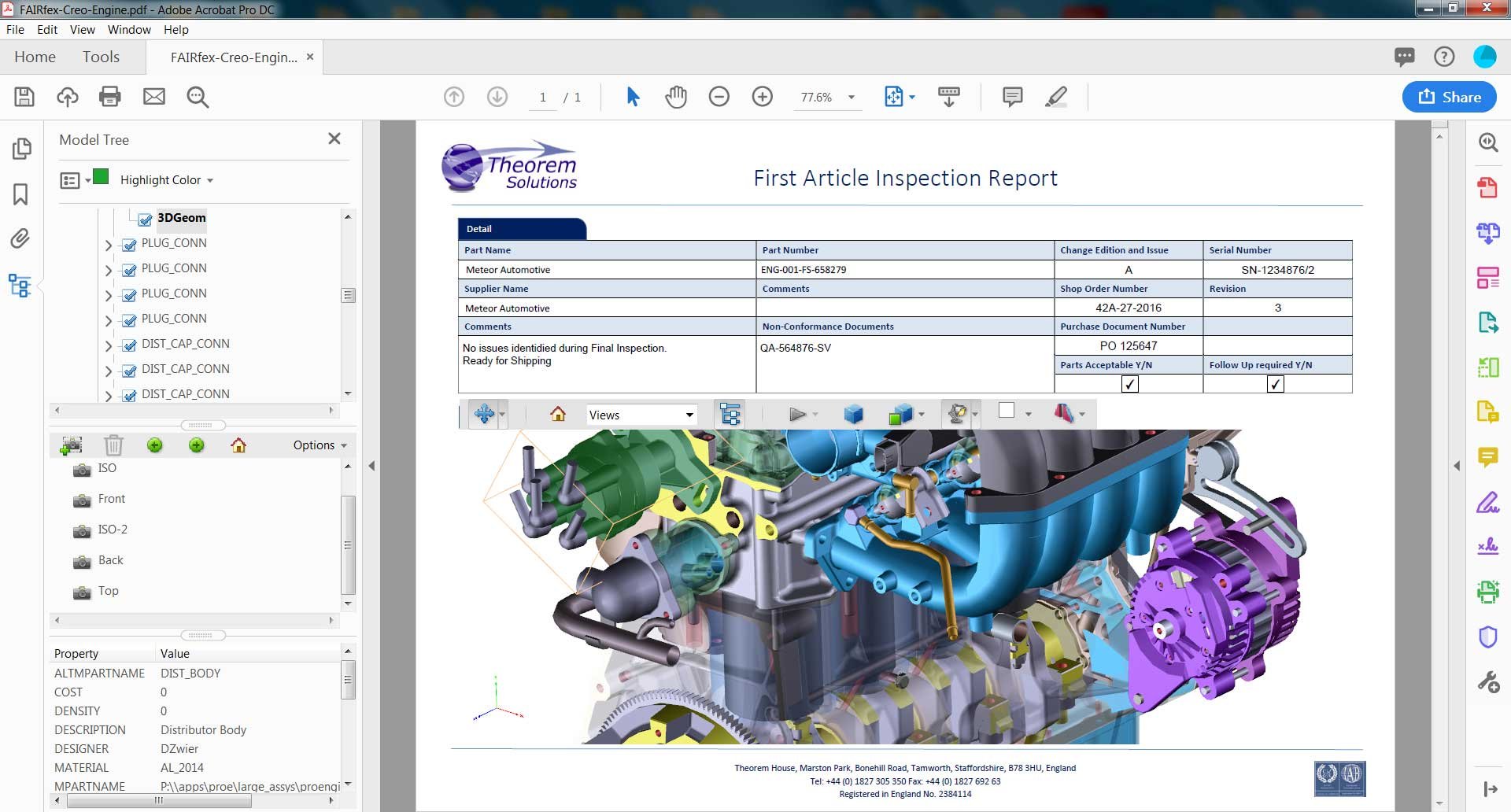

Inspection Reports for Quality and Inspection Departments

The creation of final Inspection documentation, containing interactive 3D Data using the PDF format, significantly enhances and simplifies the QA reporting function needed for components to pass quality control and move into production.

An interactive 3D representation of a specific part or component, combined with additional metadata-part descriptions, part numbers, detailed drawings and proposed changes- and created as part of the inspection process that can be annotated, with findings highlighted and shared between departments is a very powerful information communication tool indeed.

The 3D representation can be used as an additional check of inspection; visually showing what has been inspected or what needs to be inspected.

Using a QA report template that can be populated directly from source data; with data that can be pulled from all necessary departments within an organization, as well as being attached to create a data package, reduces the time needed to locate all required documents and drawings helping to improve the QA process.

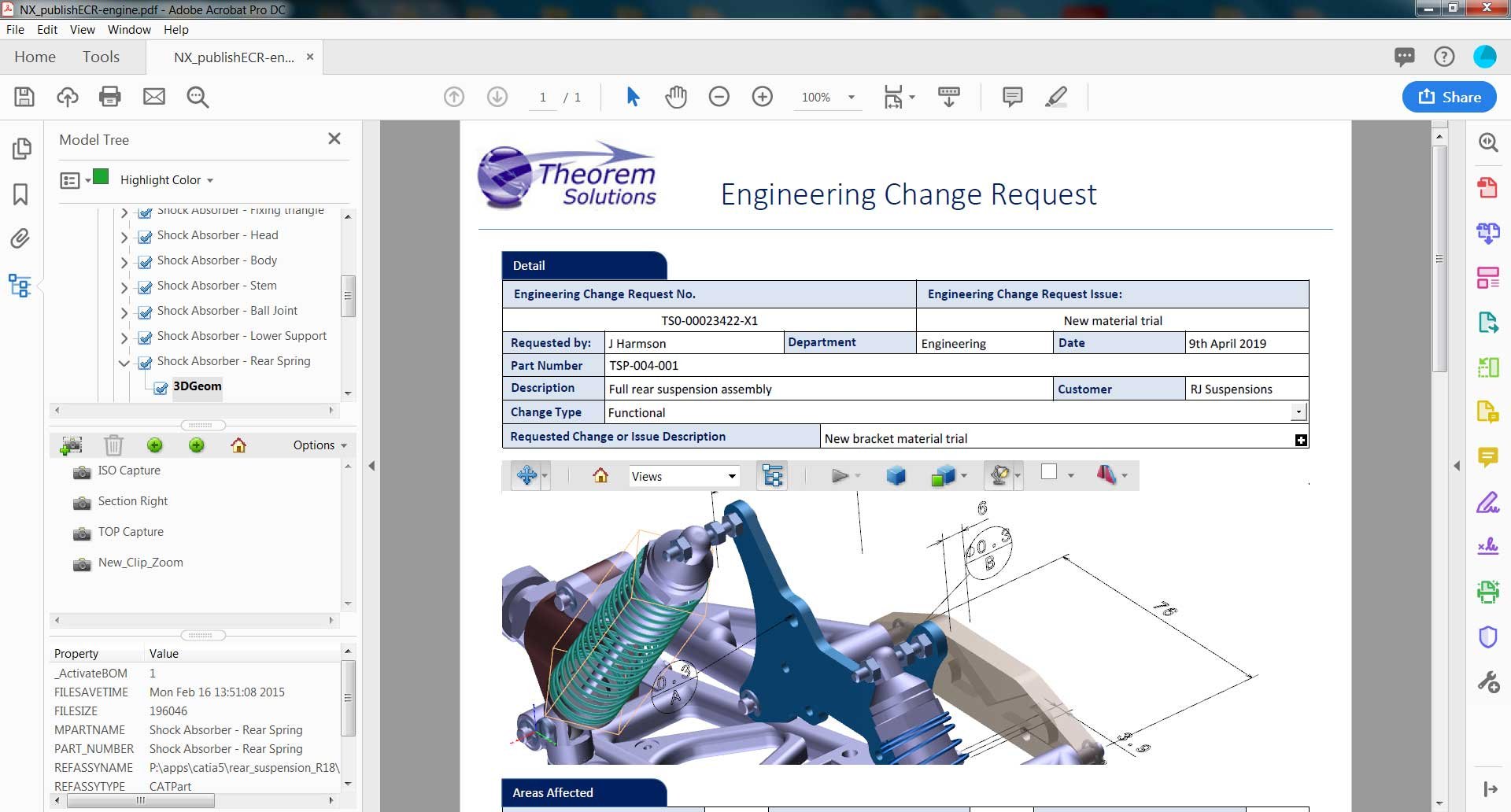

Engineering Change Request for Engineering Departments

3D PDF is the perfect mechanism to use for an Engineering Change Request Document. An interactive 3D PDF can be used to inform and update others within the Engineering department that modifications to a component are required, without needing specialist CAD or viewing applications to see the change(s) and give relevant approvals.

As with the Inspection Reports, the addition of an interactive 3D representation of a specific part or component, combined with additional metadata, proposed changes, and created as part of the ECR process that can be annotated, with notes highlighted and then shared, is a very powerful, yet simple communication tool.

As PDF doesn’t require the use of a license of Vis-Mockup to load CAD data into a specific application, for example, time will be saved and costs reduced, especially as the all necessary information can be contained and attached within a single document (technical data package); simplifying the sign off process.

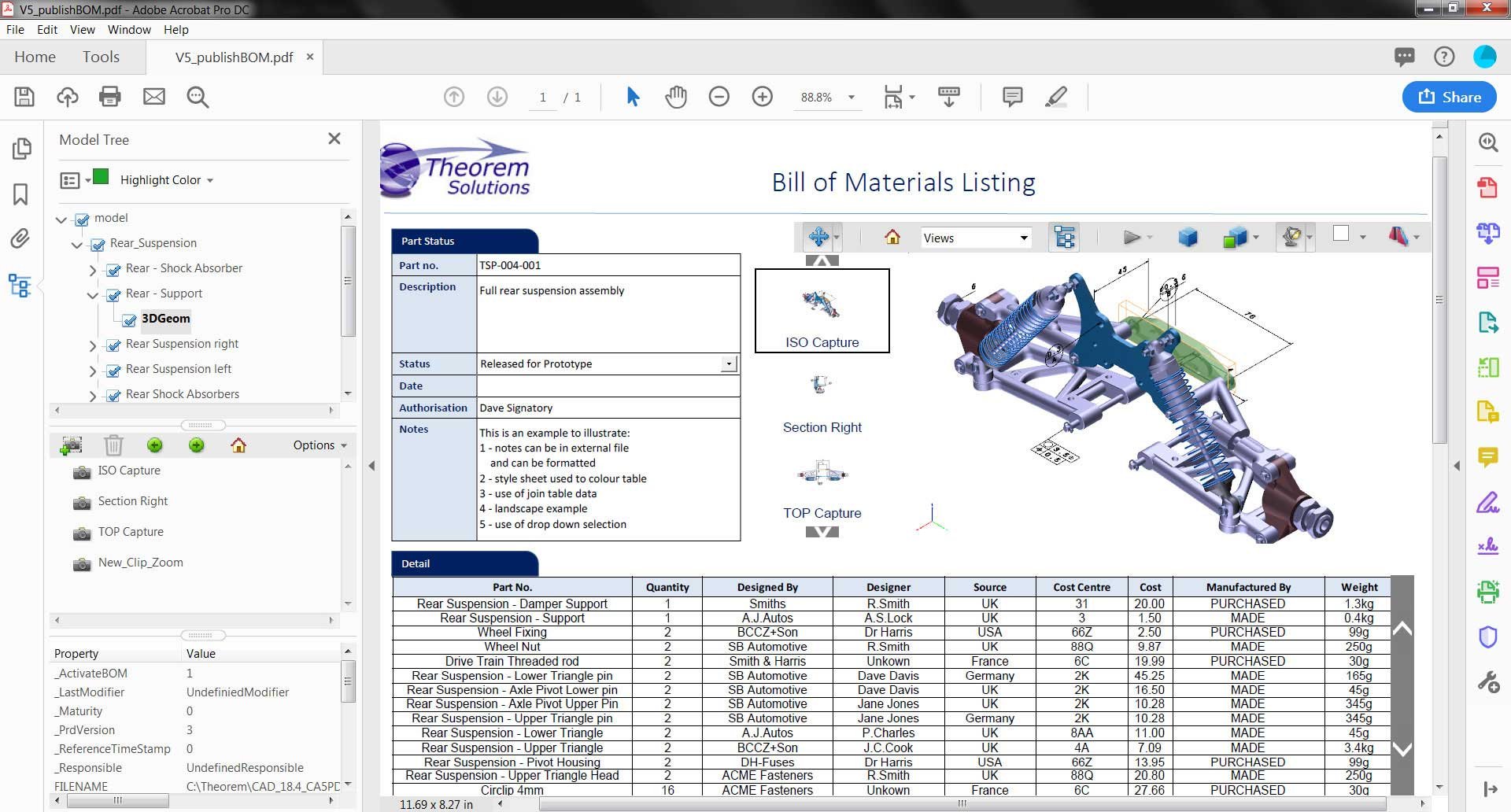

Bill of Materials (BOM) for Manufacturing Departments

When the product lifecycle is at the manufacturing stages, it is essential that staff have all the necessary pieces of information that are required to put in place the manufacturing processes needed for production.

Most of this information will be passed down from the design engineers, who will have designed the product using a CAD system. But the manufacturing engineers need more than just the design visual, they need the rest of the product information, such as dimensions and materials etc. and unless they know how to use a CAD system, they may have difficulty in accessing and understanding it. Sharing data in its native digital form requires specialist resource and training. The more traditional paper route can equally be as problematic. Both routes can be expensive and time-consuming and often require input from Engineering to make sense of the data.

Combining interactive 3D design data representations with full Product Manufacturing Information (PMI), 3D PDF documents can be used during the manufacturing process, removing the requirement for 2D drawings to be output from the CAD source data.

3D PDF allows a more thorough understanding of the product due to different views being available for interrogation, along with dimensional, tolerance, and surface finish information. Additional information can be attached to the 3D PDF document (such as spreadsheets, hyperlinks, AVI’s etc.). You can then use the 3D image embedded and any additional data, such as quantities, and cost information, and lists of raw materials, to create an MBOM, which can be shared throughout the organization and the supply chain.

11 - Collaborate

CADPublish enables organizations who design with CATIA V5, CATIA 3DEXPERIENCE Creo or NX, or who want to extend the use of their JT data to seamlessly publish that 3D data as a PDF, and take the intelligence contained within a 3D model into the world of PDF. That means anybody can consume, view and mark-up 3D data with Adobe’s ubiquitous Reader. It eliminates the need to install specialist viewing software or to be trained to use a special tool.

PDF facilitates the collaboration process internally and externally, helping speed up the development process and getting products to market faster. 3D eliminates ambiguity and enables simple documents to carry 3D data which can be viewed and interrogated by everybody in the process, not just engineering specialists. With CADPublish just doing a simple “save as”, this puts complex CAD into a PDF document. For users who need to publish 100’s or 1000’s of documents a day, a simple-to-use and automated publishing process is part of the solution.

Using PDF improves security when collaborating with business partners. PDF secures the data by providing password protection to the document, protecting your intellectual property. Publish 3D makes sure that outside of the enterprise your data is secure.

CADPublish is scalable, it provides a simple save as tool, up to a full enterprise high volume publishing solution enabling collaborative teams to quickly and easily create documentation containing interactive 3D data published directly from native CAD or PLM.

Improved collaboration will result in seamless exchanges of data and more importantly, design intent from the design engineer. This data can be analyzed up and down the supply chain and optimized for improvements to assembly, product cost, purchasing, quality, tool making, work instructions and marketing. This will undoubtedly lead to reduced lead-times, fewer mistakes and better products.

One exceptionally smart function of the new CADPublish technology is the ability to embed or package native CAD files in the same document, publishing one PDF document with every piece of collaborative information required.

12 - Data Review

Almost every department within an organization will need to discuss a product’s design at some point along the process; the question is how this can be done more efficiently and utilizing existing resource?

Product designers have a close working relationship with many different departments within an organization. They create the initial design concept/brief which would then need to be shared with colleagues to review and assess the design and provide their own input and feedback. Using 3D PDF makes this quick and easy and so speeds up the whole design cycle.

By embedding 3D viewing capability into the freely available Adobe Reader, 3D data exchange and 3D viewing become available to anyone in the world.

Using 3D PDF to review data offers the following functionalities:

- Annotations- allows additional comments to be added to the data if required and saves changing the source data.

- Saved views- save various iterations of a viewing session

- Sectioning- create a cross-section of the model

- Explode- examine the finer detail of the CAD data by breaking the assembly down

- Hide/show parts- only see what is necessary

- Standard out of the box commands- familiar to regular PDF users

- Attachments – the addition of spreadsheets, AVI’s and hyperlinks etc. create a rich data package

Data reviews today can be conducted collaboratively using the latest digital 3D technologies, enabling multiple concepts to be reviewed by departments globally, to evaluate different configurations before settling on final options for new designs, or changes to existing configurations.

13 - Data Exchange

CAD Data Exchange is often project related, and at the early exploratory stages of a project it may only take place between OEM and top Tier suppliers, and only passed between a limited set of people as feasibility and costs are considered.

Not only do the timing, volume and rate of CAD data being exchanged vary between different members of the collaboration team, it varies in its nature. For example, at RFQ (request for quotation) stage an OEM may send native CAD data, a large STEP or JT assembly to a number of key Tier 1 suppliers to enable the engineers in those companies to understand the requirement and to develop their response. This data may be accompanied by a significant number of supporting text documents that describe the project for sales, purchasing, engineering and legal departments in the companies that receive the RFQ.

All of this data could be sent as a single PDF. This way all of the related documentation, PMI, metadata etc. can all travel in a single document. In addition to this, as the PDF is CAD agnostic, it doesn’t even need a CAD license, just the free Adobe Reader- anyone can read it. This is particularly useful if one of the receiving companies is a very small or niche manufacturing company that may only be using basic low-cost CAD applications.

14 - Model-Based Definition

Model-based definition (MBD) is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define the manufacturing data that is needed to make individual components and product assemblies. The types of information included are Geometric Dimensioning and Tolerancing (GD&T), component level materials, assembly level bills of materials, engineering configurations, design intent, etc. By contrast, other methodologies have historically required accompanying use of 2D engineering drawings to provide such details.

Modern 3D CAD applications allow for the insertion of engineering information such as dimensions, GD&T, notes and other product details within the 3D digital data set for components and assemblies. MBD uses such capabilities to establish the 3D digital data set as the source of these specifications and design authority for the product. The 3D digital data set may contain enough information to manufacture and inspect product without the need for engineering drawings (which have traditionally contained such information).

In many instances, use of some information from 3D digital data set allows for rapid prototyping of product via various processes, such as 3D printing. A manufacturer may be able to feed 3D digital data directly to manufacturing devices such as CNC machines to manufacture final products.

Implementing MBD at the beginning of the product lifecycle and re-using it throughout an organisation and its supply chain enables quick, seamless and cost-effective development and deployment of products.

15 - PMI

Product manufacturing information (PMI) conveys non-geometric attributes in 3D computer-aided design (CAD) and Collaborative Product Development systems necessary for manufacturing product components and assemblies.

PMI may include geometric dimensions and tolerances, 3D annotation (text) and dimensions, surface finish, and material specifications. PMI is used in conjunction with the 3D model within a model-based definition to allow for the elimination of 2D drawings for data set utilization.

The inclusion of Theorem’s Unified Interface (UI) with Theorem’s 3D PDF Enhance product provides the opportunity for multiple PDF publishing from a single data source. Theorem’s UI helps the development and streamlining of translation and downstream processes by allowing engineering data to be filtered, viewed, interrogated, manipulated and translated interactively or in batches with the ability to publish user-specific documentation.

16 - Security

PDF files containing interactive 3D data provide a higher level of Intellectually Property (IP) security than native CAD files by allowing the documents to be password protected.

Native CAD files cannot be password protected, causing IP vulnerabilities when shared or accessed. Using 3D PDF, the CAD data can be translated into a tessellated format, with content such as features, history and constraints being removed, so that the 3D representation can be viewed and manipulated, but the native CAD data cannot be accessed or reproduced from the PDF alone.

This added functionality gives greater confidence when sharing sensitive information with partners and suppliers.

Using standard Adobe PDF security, a 3D PDF can be:

- Password protected

- Encrypted

- Data Rights Management added

- Restricted access for specific users with other applications such as LiveCycle, FileOpen etc.

A 3D PDF has the capability for the document to be annotated, and can also act as a ‘carrier’ file for additional data to be transported (such as spreadsheets, AVI Movies, hyperlinks, as well as native CAD data) and create a richer file and source of information, but still keep IP secure.

17 - Types of CADPublish

Create

Publish a 3D PDF file from within CATIA V5, CATIA 3DEXPERIENCE, Creo or NX.

- A low-cost entry into the world of 3D PDF

Enhance

Combines an interactive capability with the ability to batch process

- Supports ad hoc or volume publishing

- Enables casual users to drag and drop native CAD files

- Offers independent viewing of the native CAD file

18 - Summary

The 3D PDF format is revolutionizing the consumption and sharing of data. It is a simple and cost-effective method to leverage existing CAD and PLM assets with non-CAD users internally and externally. More importantly, the use of the interactive format is helping to reduce ambiguity and improve communication, whilst speeding up and simplifying day to day engineering and manufacturing design cycle processes. This, in turn, is helping to reduce costs, time to market and improving product quality.

3D PDF is enabling organizations of all sizes to extend the use of their native 3D CAD and Visualization data into numerous multi-disciplinary application areas and for downstream re-use that can benefit from access to 3D geometry, product structure and associated metadata.

Being able to utilize a single document as an interactive technical data package without loss of quality, is allowing a more thorough understanding of the 3D technical content of the product by staff who would not normally have access to raw engineering and CAD design data.

With Intellectual Property remaining secure in the 3D PDF format using password protection and digital rights management, data can still be exchanged without concern or risk to security.

The 3D PDF format is the future of data sharing and consumption of engineering design data throughout a product lifecycle.