The way in which we work has significantly changed in the past couple of months, and the majority of us who are still able to currently work, are now having to do so remotely.

And although it’s a situation that has meant we have had to adapt to a new way of working, it can still be ‘business as usual’ if you have the tools that enable you to carry out your day to day responsibilities.

‘Digital transformation strategy’ was a phrase that had been gaining traction in the engineering and manufacturing industries even before the current global situation. With many companies working with multiple sites, and often in multiple countries, organisations have been looking at ways to digitize processes to make them more efficient, greener and cost effective. The recent changes in how we are having to work has appeared to accelerate the need to be able to collaborate digitally even more.

In engineering and manufacturing industries, although physical production may have been reduced in the short-term, the design process doesn’t need to – collaboration is only as limited as the technology that we have access to.

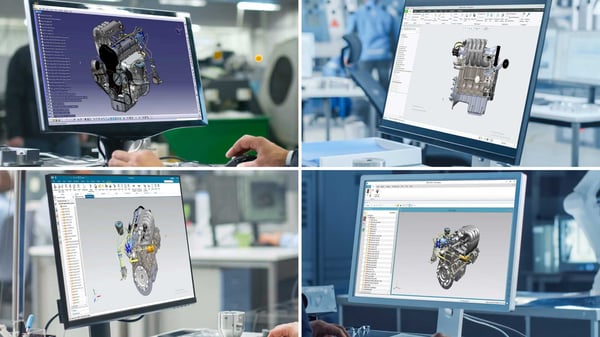

Working with incompatible CAD or PLM data has always been a problem, especially when designing products and components as part of a large supply chain. Working remotely doesn’t have to change the way in which we design, exchange data or collaborate, as data still needs to be accessed and shared.

When it comes to choosing a solution to sharing incompatible data, some companies will buy a seat of a different CAD system, so that they can access the data being sent; but this often ends up being expensive, and specialist knowledge and skills are usually required that may not exist in-house. So, it’s not always the best option, especially for smaller companies. And the data still might need to be accessed in another different CAD system further down the supply chain.

Using a data translator is a more effective option, as they simply translate 3D CAD data from one system to another. They are a high quality, cost-effective method of exchanging data between CAD or visualization systems, and you don’t need to buy additional CAD seats, as they can be used interactively from within your vendor specific application.

It may be that others in the supply chain only need to use your data for reference to help with clash detection or to show footprints of components to design around; if this is the case then it is possible to repurpose your data into lighter weight formats -such as 3D PDF- that can also help to protect your IP, and also allow you to collaborate and exchange data remotely.

Theorem have a range of solutions that enable you to carry on exchanging, and working with different types of CAD data, from wherever you are. These products support the translation of 3D Product Manufacturing Information (PMI), assembly structure, geometry, attributes and metadata for a complete Model-Based Engineering process.

As a result of Theorem’s vast experience in working with translating CAD and PLM data, and strong strategic partnerships with the major CAD vendors, including Dassault Systemes, PTC and Siemens, we use the vendor API’s and do not reverse engineer, so you can be confident that when you need to exchange and share your CAD data, that the quality and integrity of your data will not be lost.

You can find out more about Theorem’s Translate products.